Contents Catalog

The working principles, performance features, and wide applications of the 400×300 Hammer Crusher in industries such as mining, construction materials, and chemical processing. Discover how this efficient crushing equipment can enhance your production efficiency and reduce operational costs.

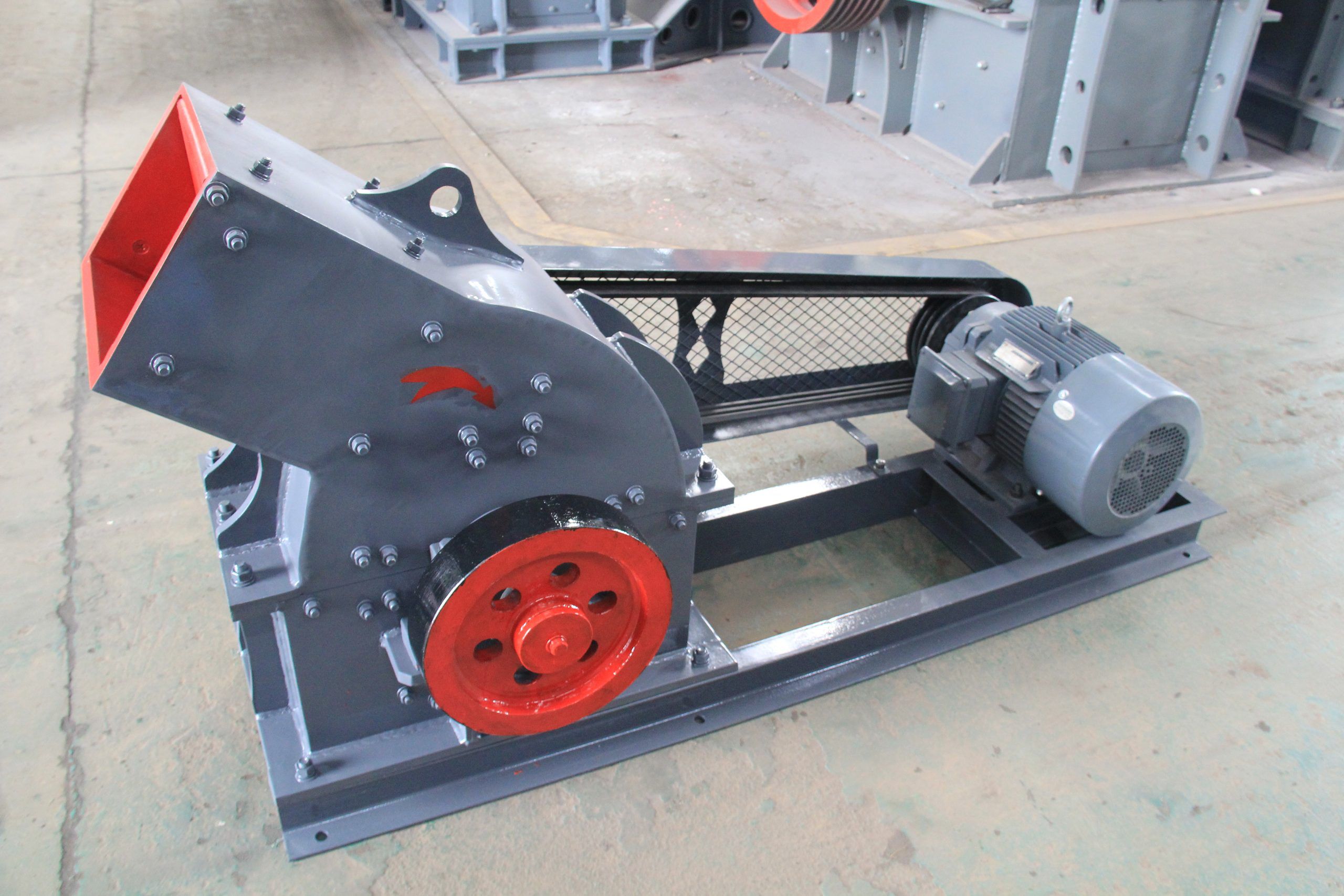

What is a 400×300 Hammer Crusher?

The 400×300 Hammer Crusher is a small to medium-sized hammer crushing equipment with a feed inlet size of 400mm×300mm. It is suitable for crushing medium-hard and brittle materials. Known for its simple structure, easy operation, and high crushing efficiency, it is an ideal choice for industries such as mining, construction materials, and chemical processing.

| Parameter | Value |

|---|---|

| Model | 400×300 |

| Feed Inlet Size | 400mm × 300mm |

| Max Feed Size | ≤200mm |

| Discharge Size | 3-30mm (adjustable) |

| Processing Capacity | 5-15t/h |

| Motor Power | 11kW |

| Rotor Speed | 1000-1500r/min |

| Equipment Weight | Approx. 1.2t |

| Overall Dimensions | 1100mm × 1050mm × 1100mm |

Working Principle of the 400×300 Hammer Crusher

- Feeding:

Material enters the crushing chamber through the feed inlet and is evenly distributed around the rotor. - Crushing:

The high-speed rotating hammers impact, shear, and collide with the material, breaking it down to the desired size. - Screening:

Crushed material passes through the screen plate, while oversized material remains in the chamber for further crushing. - Discharge:

Material meeting the size requirements is discharged from the outlet, completing the crushing process.

Key Features of the 400×300 Hammer Crusher

- High Crushing Efficiency:

Equipped with high-speed rotating hammers and an optimized crushing chamber design for efficient performance. - Adjustable Particle Size:

The discharge size can be flexibly adjusted by replacing the screen plate to meet various production needs. - Simple Structure:

Compact design for easy installation and maintenance, reducing operational costs. - Durability:

Key components are made of high-wear-resistant materials to extend the equipment’s service life. - Wide Applicability:

Suitable for crushing medium-hard and brittle materials such as limestone, coal gangue, and gypsum.

Applications of the 400×300 Hammer Crusher

- Mining Industry:

Used for crushing ores like limestone and granite, providing appropriately sized raw materials for subsequent mineral processing. - Construction Materials Industry:

Used for crushing cement clinker, gypsum, and other building materials to meet construction production needs. - Chemical Industry:

Used for crushing chemical raw materials such as phosphate rock and sulfur, supporting chemical production processes. - Other Industries:

Also used in metallurgy, energy, and other fields for material crushing operations.

Why Choose the 400×300 Hammer Crusher?

- Cost-Effective:

Offers high crushing performance at a reasonable price, making it suitable for small and medium-sized production enterprises. - Easy Operation:

Stable operation and simple controls reduce labor costs. - Convenient Maintenance:

Modular design simplifies maintenance and part replacement, minimizing downtime. - Eco-Friendly and Energy-Efficient:

Low noise and dust emissions comply with environmental standards while reducing energy consumption.

Take Action Now to Boost Your Production Efficiency!

If you’re looking for an efficient and reliable crushing solution, the 400×300 Hammer Crusher is your ideal choice. Contact us today to learn more and explore customized solutions tailored to your needs!