Contents Catalog

Recently, an environmental protection company in Jiangxi Huichang ordered an annual output of 200,000 tons of calcium hydroxide production line officially put into operation. It marks another milestone for our company’s calcium hydroxide equipment in the Jiangxi market.

Jiangxi Huichang customer calcium hydroxide production line equipment introduction:

- Processing material: Limestone

- Finished product: high purity and fine calcium hydroxide powder

- Annual production: 200,000 tons

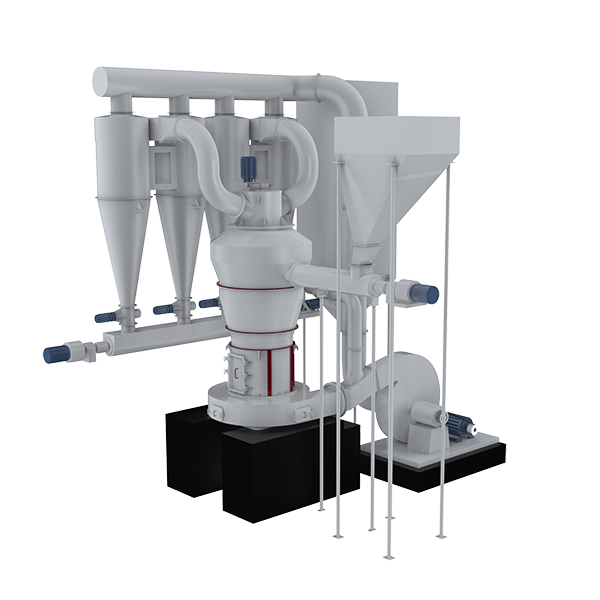

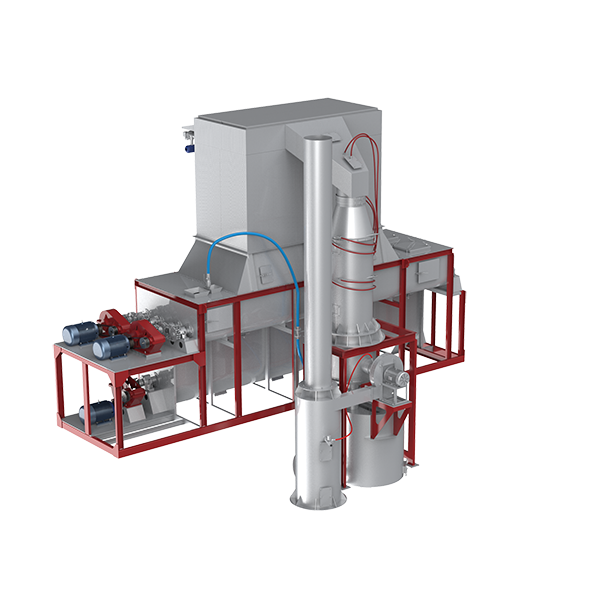

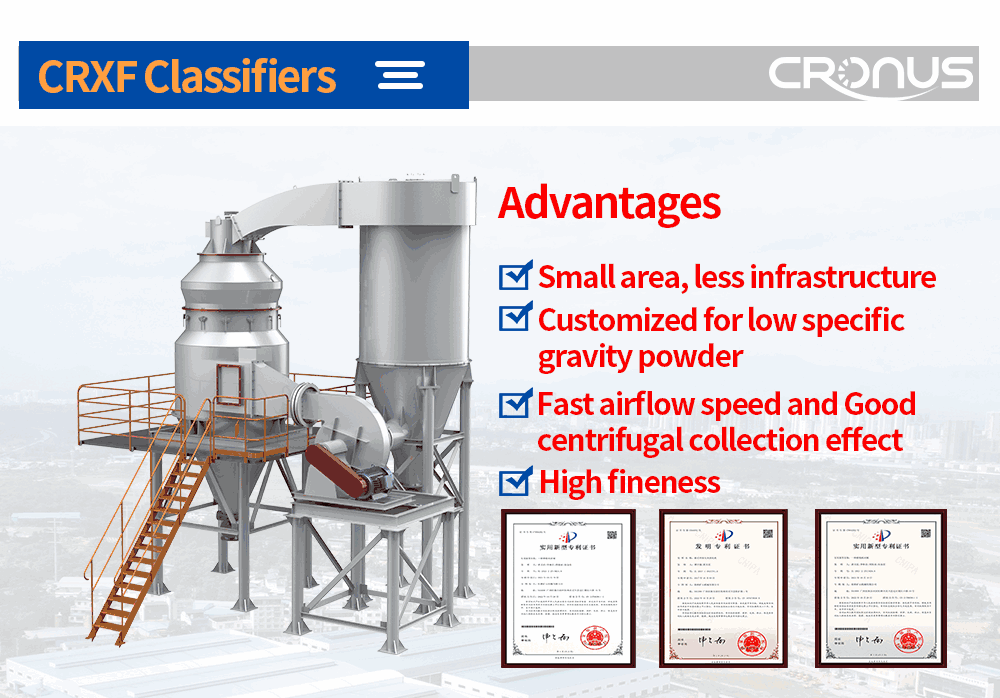

The main configurations of the line include: Kronos lime digestion equipment, a calcium hydroxide special mill, a calcium hydroxide special separator, and an atomization system. The whole production line modular design, and combined installation, greatly saved the cost of installation and floor space, compared with the traditional three-stage digestion equipment, saving the steel structure about 1 million yuan. Greatly reduce the customer’s investment cost. Combined installation, distribution, and customer maintenance costs will be very low, but also from another point of view greatly save the later use of costs.

After a tense installation of more than two months, the production line equipment was officially put into operation, after strict technical indicators testing, my company’s calcium hydroxide production line equipment produced by the calcium hydroxide has higher fineness and purity is pure, better than the domestic counterparts.

Some Pictures from the Customer site

Performance Parameters of Importance for calcium hydroxide

Most business owners emphasized the following performance parameters of calcium hydroxide:

- Purity: A high level of purity is essential as it directly affects the quality and effectiveness of the final products in which calcium hydroxide is used.

- Particle size distribution: The size of the particles influences the reactivity and solubility of the powder, which is critical in various applications.

- Chemical reactivity: This parameter determines the speed and efficiency of chemical reactions involving calcium hydroxide.

Reasons for Significance

The reasons these parameters are important include:

- Purity ensures consistent and reliable performance in industrial processes, reducing the risk of impurities causing adverse effects.

- Optimal particle size distribution enhances the homogeneity and efficiency of reactions, improving product quality and reducing production costs.

- High chemical reactivity leads to faster processing times and better outcomes in applications such as neutralization and pH adjustment.

Main Applications of calcium hydroxide

Calcium hydroxide powder finds extensive use in several areas:

- Construction: It is used in mortar and plaster for its binding and hardening properties.

- Environmental remediation: To treat acidic wastewater and soil.

- Chemical manufacturing: As a raw material in various chemical processes.

The performance parameters of calcium hydroxide identified by business owners play a vital role in determining the quality and application scope of the product. Understanding these factors is crucial for the continued growth and development of the calcium hydroxide industry.