Contents Catalog

Application of Superfine vertical roller mill

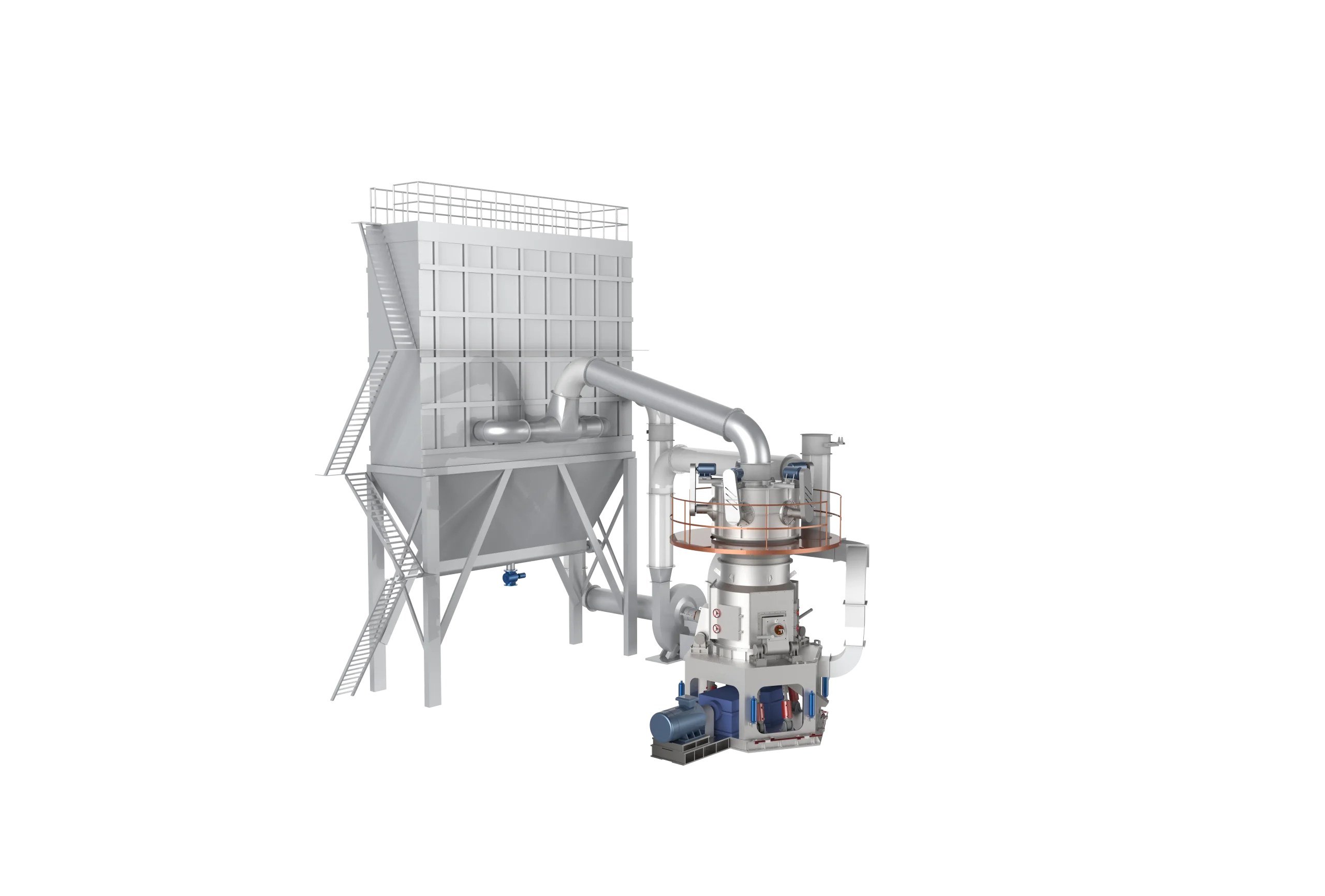

Cronus CRLMS Ultrafine Vertical Roller Mill is suitable for huge capacity producing, widely used in grinding non-flammable and non-explosive materials under 7(the Moh’s hardness), such as calcite, talcum, barite, marble, dolomite, talc, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, quartz, feldspar, etc. and other more than 150+ mineral materials.

the final fineness is 200-3000 mesh adjusted

application of stone powder

Ultrafine ore micro powder has been found to have extensive applications in various industries due to its unique properties.

in the PVC and cable industry, micro powder is an excellent filler, and it can also be used in Artificial marble, plastic, paint, and papermaking plants.

Advantages of ultra-fine vertical roller mill in processing ore fine powder

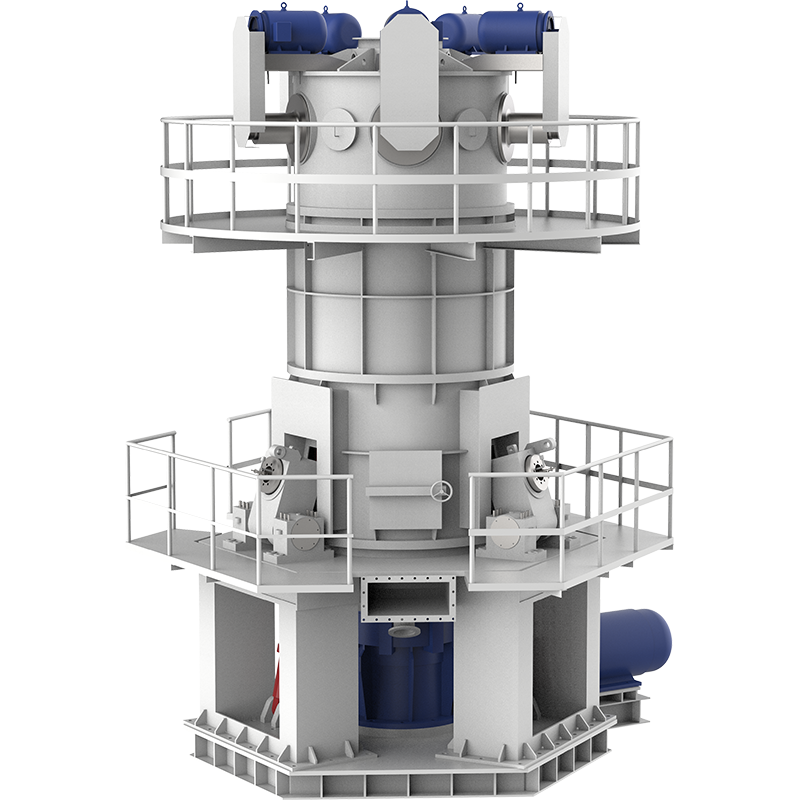

The grinding disc is driven by a motor through a reducer. The material falls to the grinding disc from the feed opening. The materials are driven to the edge of the disc by the centrifugal force and crushed into fine powders by rollers. Then, the hot air from the nozzle takes the fine powder to a high-efficiency classifier. The qualified powder is taken by the air to the powder collector to be collected, while the unqualified powder is sent back for regrinding.

1. High fineness of the finished product

200-3000 mesh adjustable , and 2 microns content >60%

2.High grinding efficiency

save 20~30% power consumption compared with the ball mill and other grinding mill machine.

3.Low noises and little dust

no direct contact between the grinding rollers and the grinding disc, so metallic impact is avoided and its noise is 20~25 decibels lower. Totally closed negative pressure operation has been employed by this vertical grinding mill, so there is little dust during the operation.

4. Low wear rate and little metallic pollution: its metal wear is only 5~10g/t.

Technical parameters of ultrafine vertical mill

| CRLMS series Superfine Vertical Roller Mill Specifications and Models | ||

|---|---|---|

| Model | CRLMS1200 | CRLMS1400 |

| Capacity (t/h) | 3.8~12.0 | 6~16.0 |

| Fineness (Mesh) | 325~1500 | 325~1250 |

| System Power (Main Motor Power+Fan Power +Classifier Electric motor Power +Auxiliary Power)(KW) | 560~600 | 700~750 |

| CRLMS1400 Heavy Superfine Calcium Carbonate Data | ||||

|---|---|---|---|---|

| Fineness (mesh) | 325 | 600 | 1000 | 1250 |

| Fineness | 15~16 | 11~12 | 7.5~8.0 | 6.0~6.5 |

| Size Distribution D97 (μm) | 45±1 | 25±1 | 13±1 | 10±1 |

| Specific Surface Area (cm²/g) | 6000 | 12000 | 14000 | 16000 |

| ±1000 | ±1000 | ±1000 | ±1000 | |

| material: calcite or marble, moh’s hardness≤3, feeding size≤10mm. | ||||

Customer site

Accessories display