Contents Catalog

Pendulum mill processed materials

The pendulum mill is suitable for huge capacity production and is widely used in grinding non-flammable and non-explosive materials under 7(the Moh’s hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash, carborundum, coal, etc.

Raymond Mill’s Requirements on Materials

➤Moh’s hardness below Grade 7

➤Moisture below 8%

➤Non-combustible and non-explosive

➤Feed size ranging from 40 to 400meshes

Calcium carbonate crushing processing, gypsum crushing processing, power plant desulfurization, non-metallic ore pulverizing, and pulverized coal preparation.

Applications: Metallurgy, chemical engineering, building materials, mining, pharmacy, cosmetics and other fields

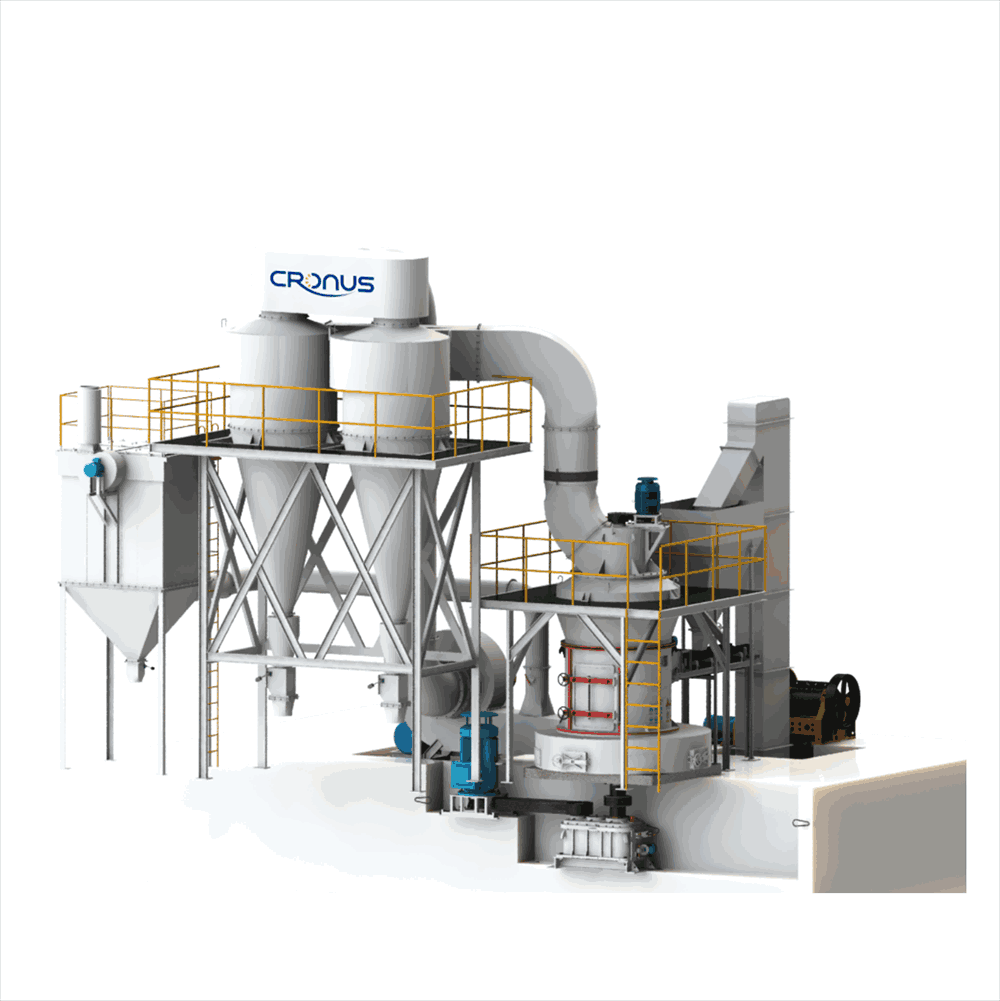

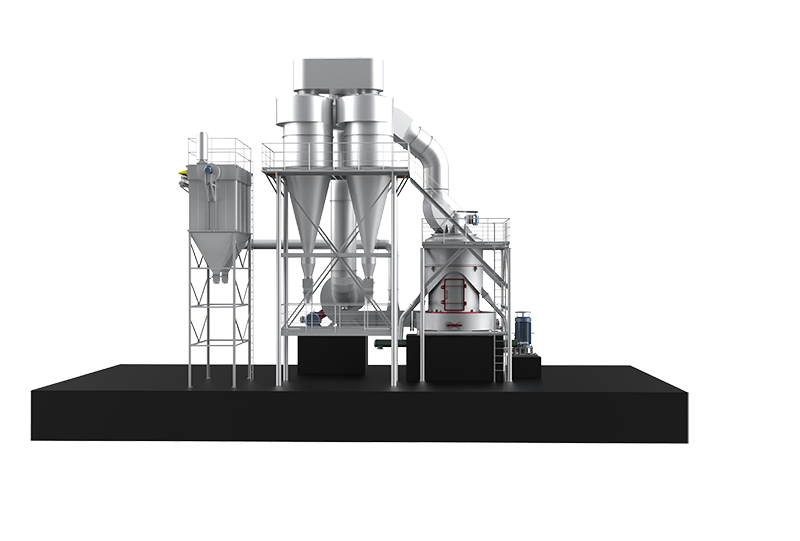

Pendulum Mill Working Principle

After jaw crushers break large bulky materials to smaller ones, elevators work to send materials to the hopper. Then, by electromagnetic vibrating feeders, broken materials are evenly and quantitatively sent to the grinding chamber of the Pendulum mill.

After grinding, materials are blown away by airflow to the powder concentrator for classifying. Under the action of the impeller of the powder selector, materials that fail to meet fineness would be sent back to the grinding chamber to get another grinding while qualified powders would be collected by a cyclone powder collector and discharged from the bottom as finished products. And, after that, the airflow would go into the fan along with the air return duct at the top of the cyclone power collector. This system adopts a closed circuit and runs under positive and negative pressure.

Because materials have a certain content of moisture, heat generated during grinding may lead to air evaporation or swell in the grinding chamber so that the amount of airflow increases sharply. Besides, if the feed port and joints of pipelines are not sealed well, external air may intrude the grinding mill and lead imbalance of airflow. So, SBM arranges exhaust valves at the air outlet of the fan to induce redundant air into the bag filter. After purifying, the redundant air is discharged. This arrangement can achieve both the balance of airflow and the eco-friendly production.

Pendulum Mill Performance Advantage

High Fineness

Low loss and high fineness: tear and wear parts use high-quality wear-resistant materials, the service life is over a year, and the final fineness is up to D97 5um

Intellectualized Design

With a centralized control electrical system, the workshop can achieve unmanned operation.

PLC intelligent control system, Siemens high-end Motor

Easy Operation

Easy to control and maintain, reliable operation.

The core components adopt high-performance, high wear resistance, and cost-saving materials.

Technical parameters of Pendulum mill

| Model | Feed particle size (mm) | Product granularity (mm) |

Overall dimensions (Length * width * height(mm) (Does not include dust collector) |

Capacity(t/h) | power(kW) | ||

|---|---|---|---|---|---|---|---|

| Main Machine | Fan | Classifier | |||||

| 4R3220 | 20 | 0.045~0.18 | 6950×4570×8295 | 1~6 | 45 | 45 | 15 |

| CR1280 | 20 | 8400×5650×8200 | 1.5~10 | 55 | 55 | 15 | |

| 5R4128 | 20 | 8660×6050×9250 | 2~15 | 90 | 90 | 22 | |

| CR1500 | 20 | 8700×5500×9250 | 3~18 | 110 | 110 | 22 | |

| CR1620A | 30 | 9670×5570×10550 | 5~22 | 160 | 132 | 30 | |

| CR1700 | 30 | 9670×5570×10550 | 6~28 | 185 | 160 | 37 | |

| CR1850 | 30 | 10455×6830×9815 | 6.5~30 | 200 | 200 | 37 | |

| CR1920 | 30 | 13312×7690×9815 | 7.5~33 | 220 | 200 | 45 | |

| CR2150 | 30 | 11080×7600×11150 | 10~40 | 250 | 250 | 45 | |

| CR2500 | 35 | 11480×7730×11250 | 11.5~50 | 280 | 280 | 45 | |

How to Increase the Yielding of Pendulum Mill?

The jaw crusher is a large crusher installed and receives no-load testing in the manufacturer’s workshop. However, it is disassembled into components for transport.

Do a good job with daily maintenance of the Pendulum mill.

Correct operation of the Raymond Mill is a must. Improper operation may cause damage to the Pendulum mill and shorten its service life, which may cause considerable economic losses due to long-term shutdown.

Control the feed standard of the Pendulum Mill.

OUR Service