Contents Catalog

Raymond Mill is a kind of high-efficiency powder making equipment widely used in mining, building materials, chemical industry, metallurgy and other industries. It is mainly used for grinding non-flammable and explosive minerals (such as limestone, calcite, barite, talc, marble, gypsum, etc.)

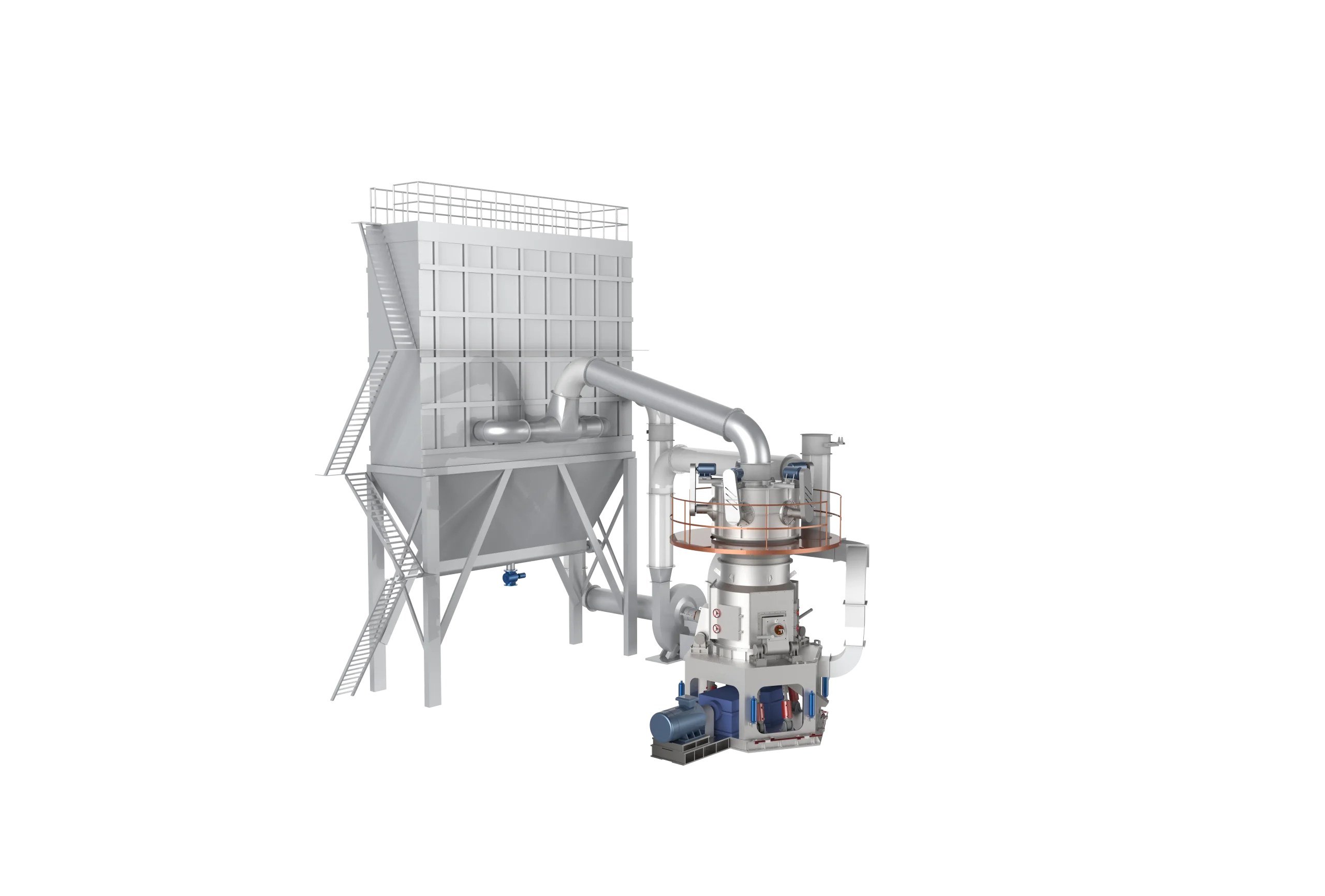

CRRM1920 Raymond Mill

Product fineness: 80~325 mesh

Product capacity: 7.5~33t/h

Application scenarios: The equipment is suitable for glass, rubber, pesticides, enamel, paint, phosphate fertilizer, papermaking and other industries, and can grind talc, barite, calcite, limestone, manganese ore, iron ore, chrome ore, quartz, gypsum, bentonite and other materials.

Main structure of CRRM1920 Raymond mill

Main machine: including grinding roller, grinding ring, scraper and other parts, responsible for grinding materials.

Analyzer: used to control the fineness of the finished product, and the particle size of the powder is controlled by adjusting the speed of the analyzer.

Fan: blows the ground powder into the analyzer for sorting.

Cyclone collector: used to collect qualified finished powder.

Pipeline system: connects various components to ensure smooth airflow

Production background of CRRM1920 Raymond mill

CRRM1920 Raymond MillRaymond Mill is developed by Cronus with international expertise and proprietary innovations, combining imported core technology with decades of practical engineering experience. As a leading manufacturer in China’s powder processing industry, Cronus continuously improves its designs to provide high-performance, reliable grinding solutions.

CRRM series Raymond Mills adopt optimized structural design and high-quality wear-resistant materials to ensure long-term stability, energy saving and precise particle control. CR mills are recognized worldwide for their durability and excellent grinding performance and have become the first choice for industrial mineral processing.

Key advantages:

✔ Patented technology – improves grinding efficiency and service life

✔ Proven reliability – low maintenance cost and stable operation

✔ Global recognition – trusted by customers around the world

For demanding grinding applications,CRRM1920 can provide consistent quality and productivity.

Functional characteristics of CRRM1920 Raymond mill

CR1920 Raymond Mill – Precision Grinding for Chemical and Industrial Applications

Designed for processing non-flammable, non-explosive materials (Mohs hardness <7, moisture ≤6%), the CRRM1920 Raymondprovides efficient grinding in key industries:

- Chemicals: pesticides, coatings, enamels

- Industrial Materials: glass, rubber, paper

- Minerals: talc, barite, limestone, gypsum, bentonite, quartz, iron/manganese/chrome ores

Key Specifications

- Maximum feed size: 35 mm

- Adjustable fineness: 80–325 mesh

- Capacity: 15–80 t/h (high efficiency range)

- Customizable: Upgradable to integrated pulverizer system

Optimized for performance and product value enhancement, this mill combines precision grinding with operational flexibility.

Raymond Mill Parameter Comparison Table

| Model | Max. Feed Size (mm) | Finished Particle Size (mm) | Dimensions (L×W×H) (mm) (Excl. Dust Collector) | Output (t/h) | Power (kW) |

|---|---|---|---|---|---|

| Main Motor | |||||

| 4R3220 | 20 | 0.045~0.18 | 6950×4570×8295 | 1~6 | 45 |

| CRRM1280 | 20 | 0.045~0.18 | 8400×5650×8200 | 1.5~10 | 55 |

| 5R4128 | 20 | 0.045~0.18 | 8660×6050×9250 | 2~15 | 90 |

| CRRM1500 | 20 | 0.045~0.18 | 8700×5500×9250 | 3~18 | 110 |

| CRRM1620A | 30 | 0.045~0.18 | 9670×5570×10550 | 5~22 | 160 |

| CRRM1700 | 30 | 0.045~0.18 | 9670×5570×10550 | 6~28 | 185 |

| CRRM1850 | 30 | 0.045~0.18 | 10455×6830×9815 | 6.5~30 | 200 |

| CRRM1920 | 30 | 0.045~0.18 | 13312×7690×9815 | 7.5~33 | 220 |

| CRRM2150 | 30 | 0.045~0.18 | 11080×7600×11150 | 10~40 | 250 |

| CRRM2500 | 35 | 0.045~0.18 | 11480×7730×11250 | 11.5~50 | 280 |

| CRRM2750 | 35 | 0.045~0.18 | 17000×11000×15000 | 15~80 | 450 |

Note: The above data is for reference only. Please refer to the actual product or manual for detailed specifications.

Product advantages of CRRM1920 Raymond mill

CRRM1920 Raymond Mill Technical Specifications

Advanced Vibration Control System

- 75% lower vibration than conventional mills

- Quiet operation with noise levels below 75dB

Next-Generation Structural Design

- Energy-efficient grinding with 30% higher efficiency

- Dual-mode reducer (electric/pneumatic) for plug-and-play operation

Smart Control System

- One-touch automated operation with precision parameter adjustment

- Heavy-duty wear-resistant drive system with 10,000+ hour lifespan

Optimized Airflow System

- Variable-speed fan for optimal material flow control

- Zero-resistance airflow design enhances output purity

Reliable Performance with Easy Maintenance

[Request Technical Documentation] → (Complete specifications available)

(All performance data verified per ISO 9001-2015 testing standards)

For customized Raymond mill solutions, technical support or detailed quotes, please feel free to contact our team. Cronus is committed to providing efficient and reliable grinding equipment that meets your needs.

📞 Contact Cronus today and let us find the perfect Raymond mill for your application.