Contents Catalog

Applicable material of CLGM series ring roller mill

CRGM series ring roller mill is suitable for the super fine grinding of all kinds of crisp materials whose Moh’s hardness is below 7, such as calcium carbonate, barite, dolomite, calcite, limestone, kaolin, bentonite, marble, gypsum, quartz, feldspar, clay, talc, fluorite, white mud, mica, refractory material, glass, total about 1000 kinds of materials.

The fine powder processed by the ore ultrafine roller mill can be widely used in PVC, paint, construction, petrochemical, stone paper, and other industries, and is the food for industrial production.

Working principle of ultra-fine ring roller mill

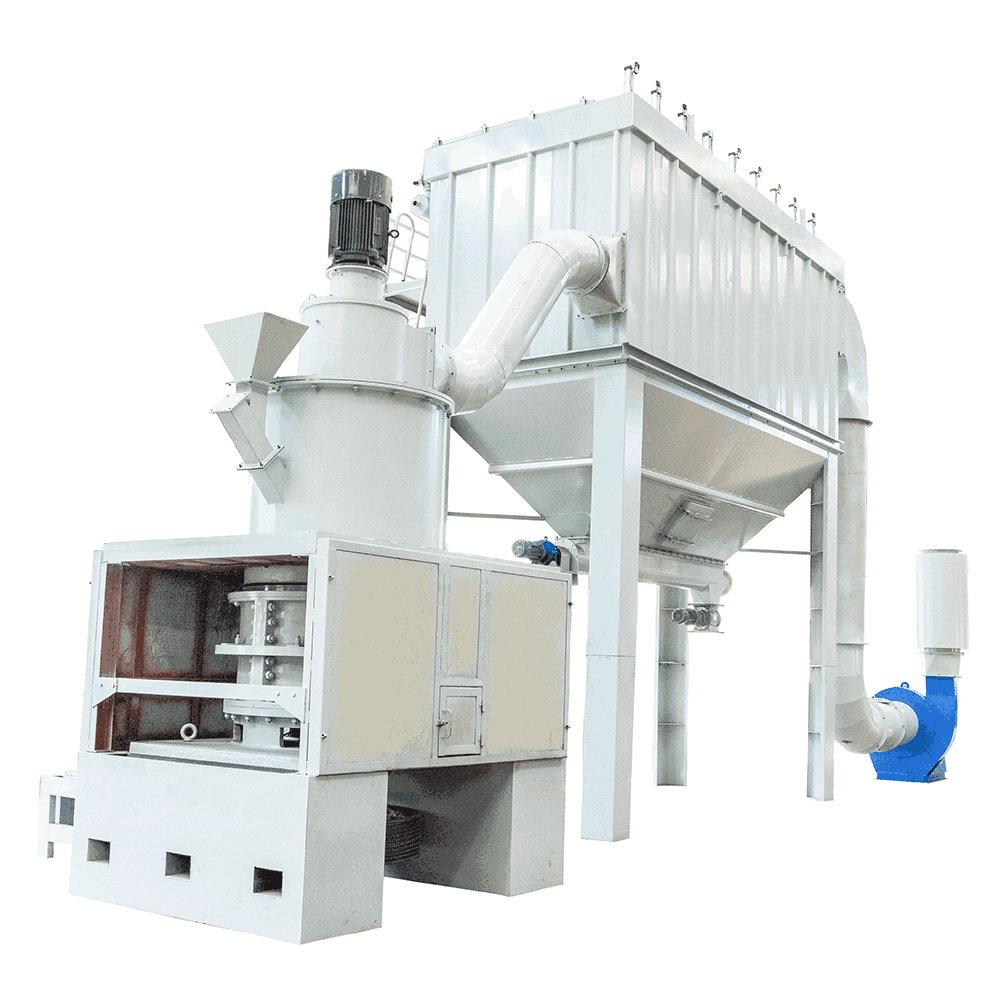

Micro Powder Grinder is mainly formed by a mill body, blower fan, ultra-fine analyzer, finished product cyclone container, bag de-duster, and air pipe. The elevator, storage bin, electric control cabinet, powder feeder and crusher are optional for the demands of customers.

When the grinding mill is at work, the main bearing and each dial are driven by an electromotor through the reducer, and all the grinding rollers are rolling in the ring channels driven by the dial through a plunger. The materials are driven to the edge of the turn plate by the centrifugal force and fall into the grinding chambers. The high-pressure air blower constantly inhales air, and airflow with crushed materials is brought to the classifier whose high-speed impeller will screen the airflow: The unqualified particle size will fall and return to the mill for being reground. In contrast, the qualified particle size mixed with air will go into the cyclone powder collector. Most qualified powders will fall and exit from the discharging valve at the bottom; A small proportion of the fine powders, with airflow, moves to the dust cleaner. The conveyor sends the materials from the above two lots to get the finished powders packed. In addition, filtered clean air will be emitted from the muffler in the end.

Advantages of ultra-fine roller mill

| mesh (D97) | CRGM1000X | CRGM2000X | CRGM3000X | ||||||

|---|---|---|---|---|---|---|---|---|---|

| capacity (kg/h) | power consumption (kW/h) | total power (power) | capacity (kg/h) | power consumption (kW/h) | total power (power) | capacity (kg/h) | power consumption (kW/h) | total power (power) | |

| 800 | 2500~2800 | 43 | 152kw | 4000~4500 | 40 | 237kw | 5500~7000 | 37~38 | 287~340kw |

| 1250 | 1500~1800 | 67 | 4000~4500 | 68 | 3500~4000 | 50~56 | |||

| 1500 | 1000~1300 | 92 | 4000~4500 | 92 | 2500~3000 | 67~70 | |||

| 2000 | 650~750 | 125 | 4000~4500 | 110 | 1500~2000 | 100~114 | |||

| 2500 | 600~650 | 135 | 4000~4500 | 119 | 1100~1500 | 134~153 | |||

| 3000 | / | / | / | / | 1000~1200 | 183~208 | |||

| mesh (D97) | CRGM3000C | mesh (D97) | CRGM1000C | ||||

|---|---|---|---|---|---|---|---|

| capacity (kg/h) | power consumption (kW/h) | total power (power) | capacity (kg/h) | power consumption (kW/h) | total power | ||

| 200 | 1300~1500 | 14~16 | 280kw | 400 | 5500~6200 | 27 | 237kw |

| 325 | 11000~12000 | 18~20 | 600 | 4000~4500 | 38 | ||

| 400 | 9000~9500 | 21~24 | 800 | 3600~4300 | 45 | ||

| 600 | 6500~7500 | 28~32 | 1250 | 1800~2300 | 80 | ||

| 800 | 6000~6500 | 33~37 | / | / | / | ||

Customer site of ring roller mill

if you are interested in our machine and do not know how to choose the match machine, please keep in touch with us by WhatsApp or call us at : +86-19921221418

Related Products

What is the difference between a ring roller mill and a general stone mill

ring roller mill has about more than 21 rollers in its body, so it can process higher fineness than a general stone mill. In general, can be reach 3000 mesh and also can be adjusted from 300 to 3000 mesh.

What is the difference between a ball mill and a ring roller mill?

The ball mill is generally used to produce mineral powder below 600 mesh, with a large output.

The roller mill is generally used to produce more than 1000 mesh of mineral powder, relative to the ball mill, the output is smaller.