Contents Catalog

- 1 Fully Automatic Double Rollers Crusher

- 2 How Double Roll Crushers Work

- 3 Applicable materials|Application scope of Double rollers crusher

- 4 Advantage of Double rollers crusher

- 5 Parameter of double rollers crusher

- 6 Why choose Cronus?

- 7 50 years experience in producing double rollers crusher

- 8 RFQ About Double Rollers crushers

- 8.1 Q: Can I visit your factory?

- 8.2 Q: What about the warranty of your equipment? Do you supply spare parts?

- 8.3 Q: Do you provide after-sales service?

- 8.4 Q :Do you provide equipment operation training?

- 8.5 Q: Do you provide a production flow chart?

- 8.6 Q: Can you test our sample raw material?

- 8.7 Q: Have you made the whole stone-crushing line?

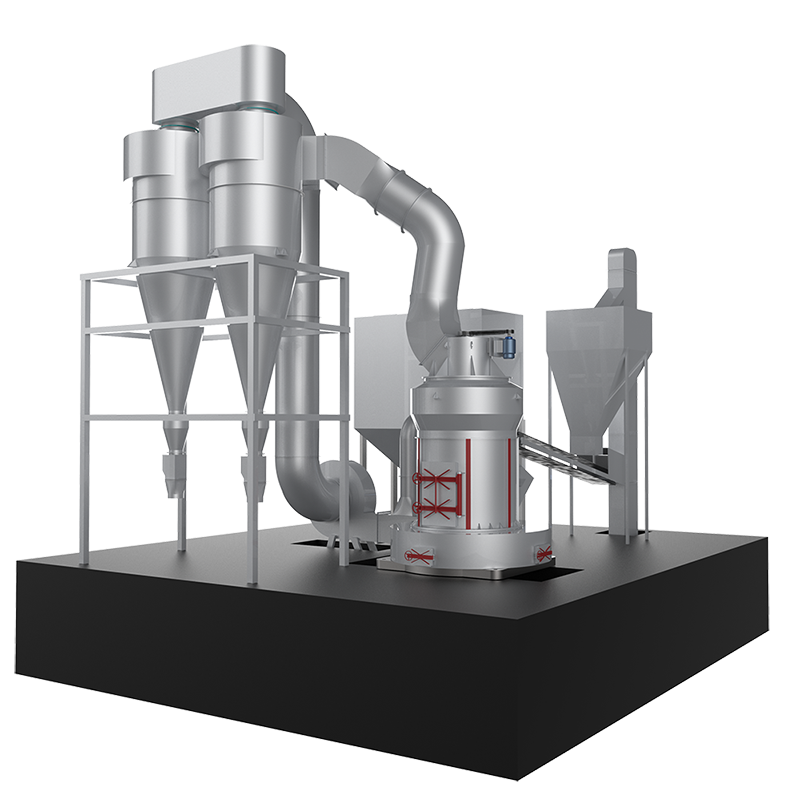

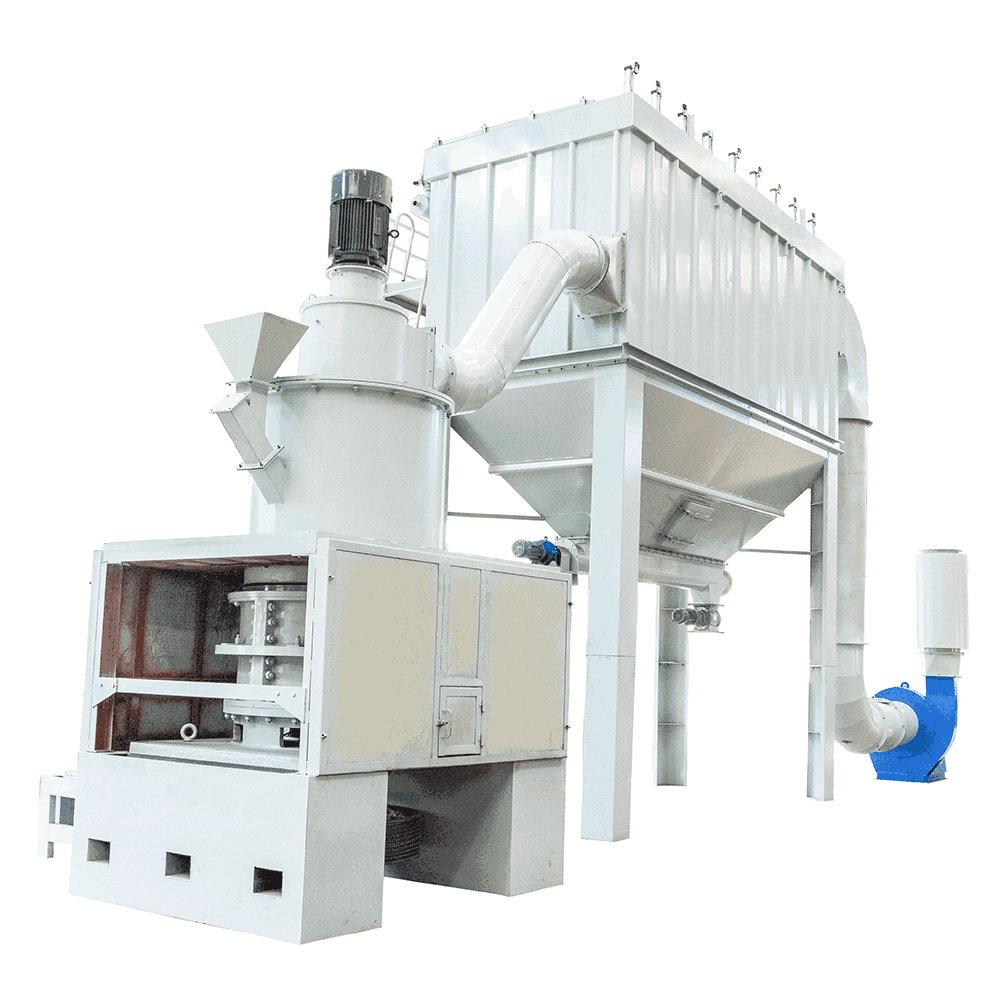

Fully Automatic Double Rollers Crusher

The double rollers crusher is another breakthrough in the field of sand and gravel aggregate production equipment manufacturing.

How Double Roll Crushers Work

Operating Double Roll Crushers is quite simple. Whether it is a single or dual drive arrangement, the rolls are powered by electric motors and V-belt drive configurations, resulting in reliable and quiet operation. If it is a single-drive arrangement, power is transferred from the driven roll to the non-driven opposing roll by an interstage V-belt drive. If it is a dual-drive configuration, each roll is powered independently through a motor and V-belt drive.

During normal operation, the material is fed between the crushing rolls. A combination of compression and shear forces created between the opposing rolls reduce the feed material to the desired product size while producing a cubical product with minimum fines.

Cronus’s mechanical tramp relief systems employ a spring-and-toggle mechanism that activates whenever an uncrushable object enters the crushing chamber. Once an excessive force is applied to the movable roll, the toggles break open to allow the uncrushable item to pass. The high torsion springs then close the toggles, returning the movable roll to the previous setting. The crusher continues to operate uninterrupted.

Optional features include hydraulic product adjustment, roll scrapers, automatic lubrication, wheeled support base and other custom solutions.

The Double rollers crusher is a two-roll sand-making machine that uses two motors to drive two roller shafts to squeeze and grind materials. The double roller crusher is mainly used for fine crushing operations with particle size requirements of less than 80mm and finished products of 50-20mm.

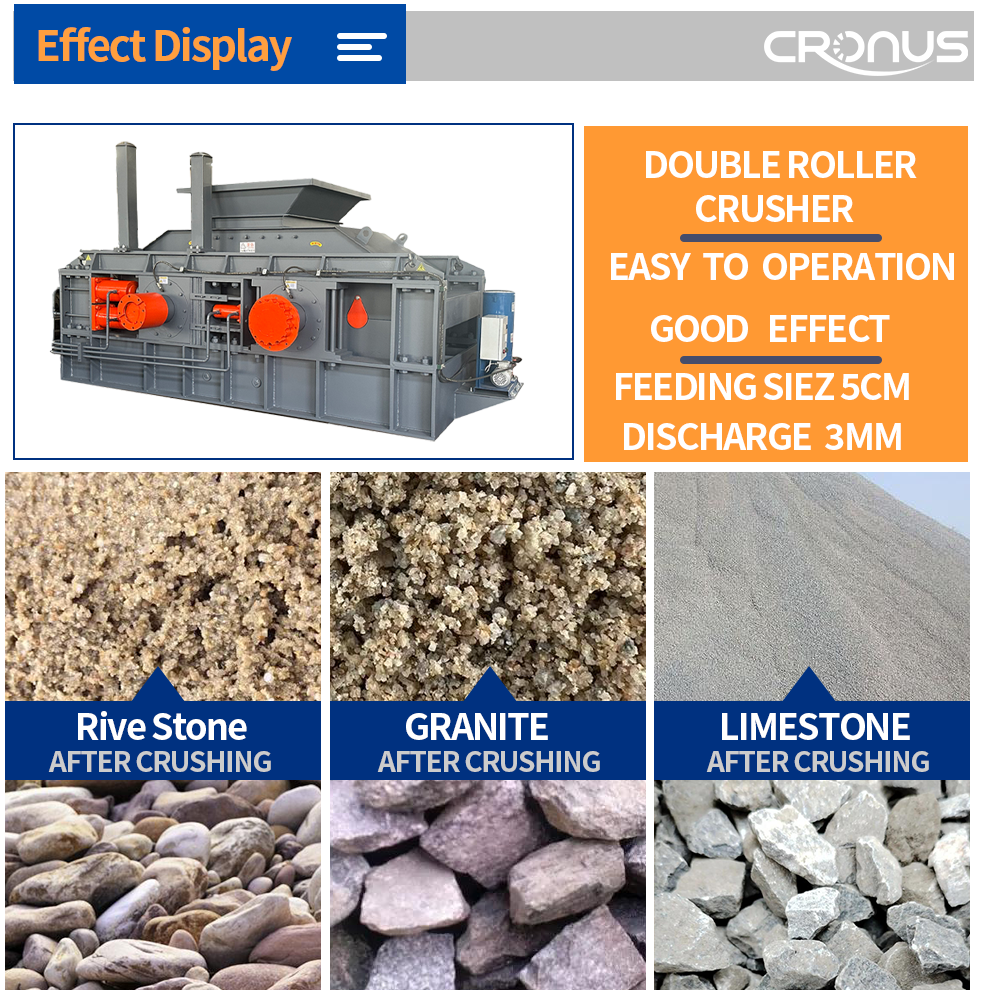

Applicable materials|Application scope of Double rollers crusher

River pebble, Calcite, quartzite, marble, cobble, bentonite, iron ore, bluestone, mountain stone, water slag, limestone, weathered sand, Diabase, granite, and basalt.

Highway, railway, high-rise buildings, municipal, hydropower dam construction, concrete mixing station, sand and stone field, etc.

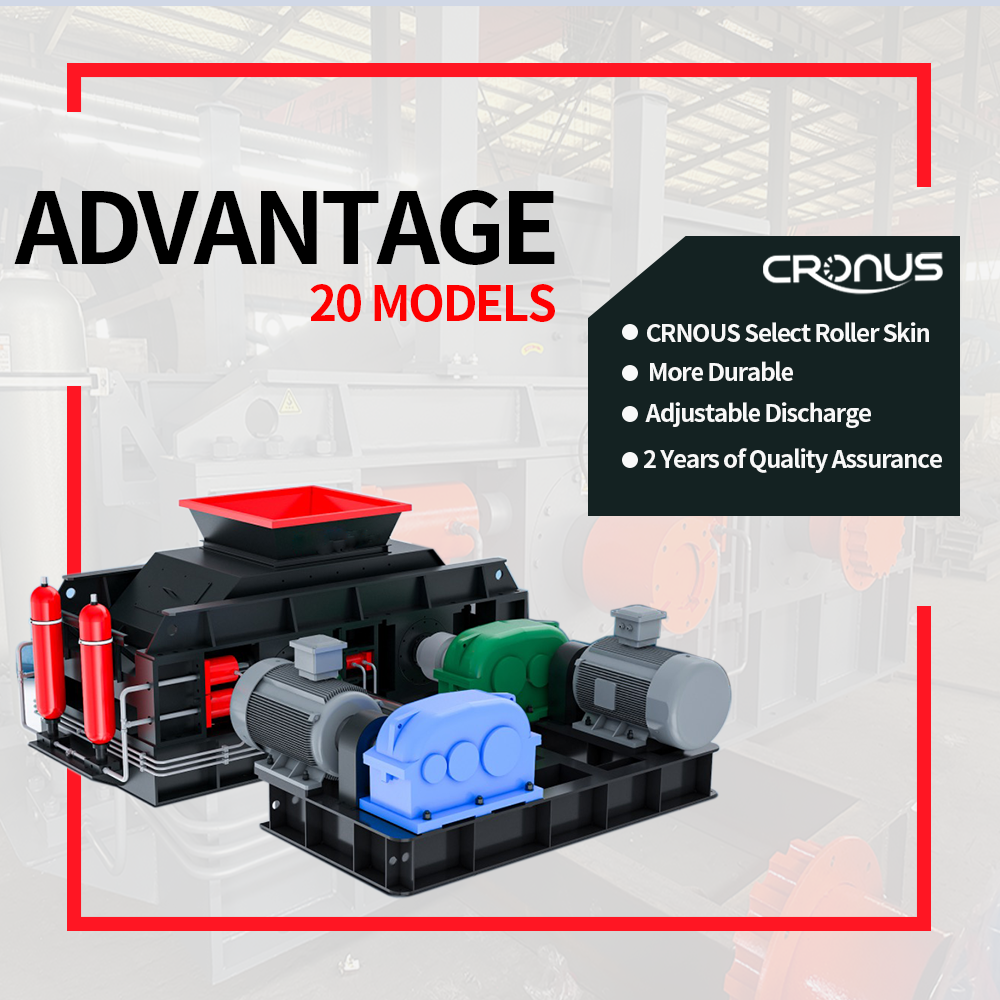

Advantage of Double rollers crusher

1. High crushing ratio and high production capacity The double-roller crusher is a double-roller sand-making machine that uses two motors to drive two roller shafts to squeeze and grind materials.

2. More crushing and less grinding, full grain size The production efficiency of the mill can be improved by crushing more and grinding less—delicate and high-quality finished products.

3 . Long service life and low operating costs The roller skin is made of wear-resistant materials with strong impact resistance and high wear resistance. It has a small loss and low failure rate when crushing materials. In the later stage, it can reduce maintenance costs, have low operating cost,s and long service life.

Parameter of double rollers crusher

Specification and model | Roll diameter (mm) | Feed size (mm) | Productive capacity (t/h) |

2PGT400×250 | φ400 | ≤25 | 2-10 |

2PGT400×400 | φ400 | ≤25 | 5-12 |

2PGT610×400 | φ610 | ≤30 | 5-20 |

2PGT750×500 | φ750 | ≤30 | 10-40 |

2PGT800×600 | φ800 | ≤40 | 12-50 |

2PGY800×800 | φ800 | ≤40 | 40-50 |

2PGY800×1000 | φ800 | ≤40 | 50-80 |

2PGY1000×800 | φ1000 | ≤40 | 50-80 |

2PGY1000×1000 | φ1000 | ≤40 | 80-100 |

2PGY1200×1000 | φ1200 | ≤60 | 100-120 |

2PGY1200×1200 | φ1200 | ≤60 | 120-150 |

2PGY1500×1000 | φ1500 | ≤80 | 150-200 |

2PGY1500×1200 | φ1500 | ≤80 | 200-250 |

2PGY1800×1000 | φ1800 | ≤100 | 250-300 |

2PGY2000×1200 | φ2000 | ≤120 | 300-400 |

Why choose Cronus?

1. easy to operation

2.1-5 mm adjustable discharge size

3.20 cm thick roller skin, no wear parts in 3 years

4. low over-crushing rate ,high capacity

5.no screen bottom, no blocking problem

6 .Suitable for upgrading old sand factories

50 years experience in producing double rollers crusher

RFQ About Double Rollers crushers

-

Q: Can I visit your factory?

A: Yes. Many domestic and overseas customers visit our factory every year.

-

Q: What about the warranty of your equipment? Do you supply spare parts?

A: Our warranty is 1 year (12 months), and we can supply spare parts also.

-

Q: Do you provide after-sales service?

A: Yes. We have a professional after-sale service team to promptly and thoroughly solve your problems.

-

Q :Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passport.

-

Q: Do you provide a production flow chart?

A: Yes. Our experienced engineers specialize in designing process flow for stone-crushing plants and various ores beneficiation lines.

-

Q: Can you test our sample raw material?

A : Yes. You can send your samples to us for testing and analysis.

-

Q: Have you made the whole stone-crushing line?

A: Yes. We have made many large-scale scale stone-crushing line at home and abroad.