Contents Catalog

1.Application of Ca(OH)2

Purity requirements for calcium hydroxide in different industries

Medicine Ca(OH)2 >96%

Plastic Ca(OH)2 >96%

Chemical Ca(OH)2 >94%

Fiber Ca(OH)2 >96%

Leather Ca(OH)2 >94%

Desulfurization Ca(OH)2 >92%

Petrochemical Ca(OH)2 >94%

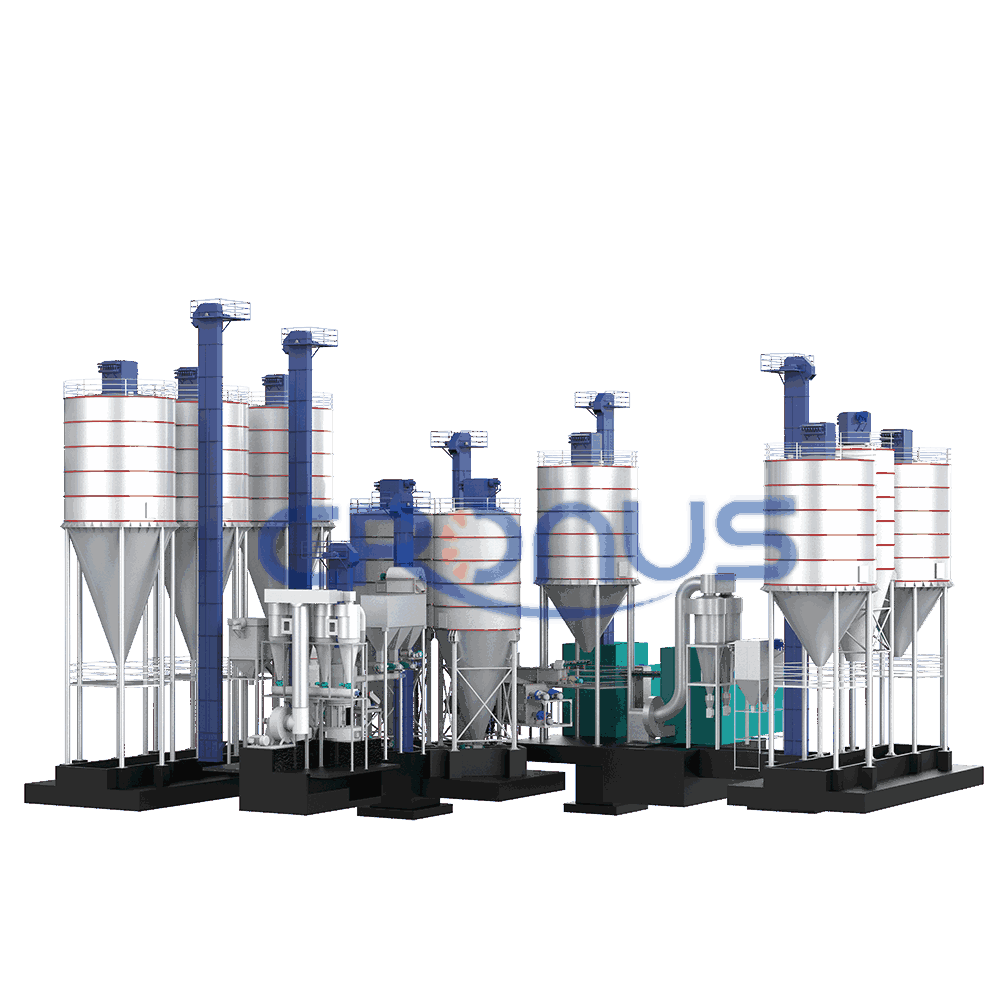

The components of Hydrated Lime Production Line

CRQ calcium hydroxide production line (Hydrated Lime Production Line) is Cronus to explore the lime industry and kiln deep processing development direction, after many tests and improvements, the successful development of lime deep processing technology and equipment. The whole production line is mainly composed of CRS lime slaker, CRLM calcium hydroxide special grinding machine, a fine powder separator with three parts, advanced technology, energy saving and environmental protection, intelligent control, greatly improved quality of products, reduced operating costs, an ideal new intelligent environmental protection calcium hydroxide production line.

Five modules

1

Crusher module

Basic configuration of crushing module

- hopper

- de-ironing separator

- pulse dust collector

- PEX250x400 jaw crusher

- NE50 elevator

- Calcium hydroxide raw material hopper

- vibration motor

- material leveling device

- gate valve

2

Slaking module

Basic configuration of the Slaking module

- type 500 belt scale

- CRSH15T

- NE50 elevator

- Pneumatic three-way distributor

- φ3820 digestion tank

- pulse dust collector

- Antispin level device

- vibration motor

- gate valve

3

Crusher module

Basic configuration of Separating module

- 26L type star discharge valve

- GL325 screw conveyor x2

- NE50 elevator x 2

- Rotary screen

- CRXF5R powder separator

- Pneumatic three-way distributor

4

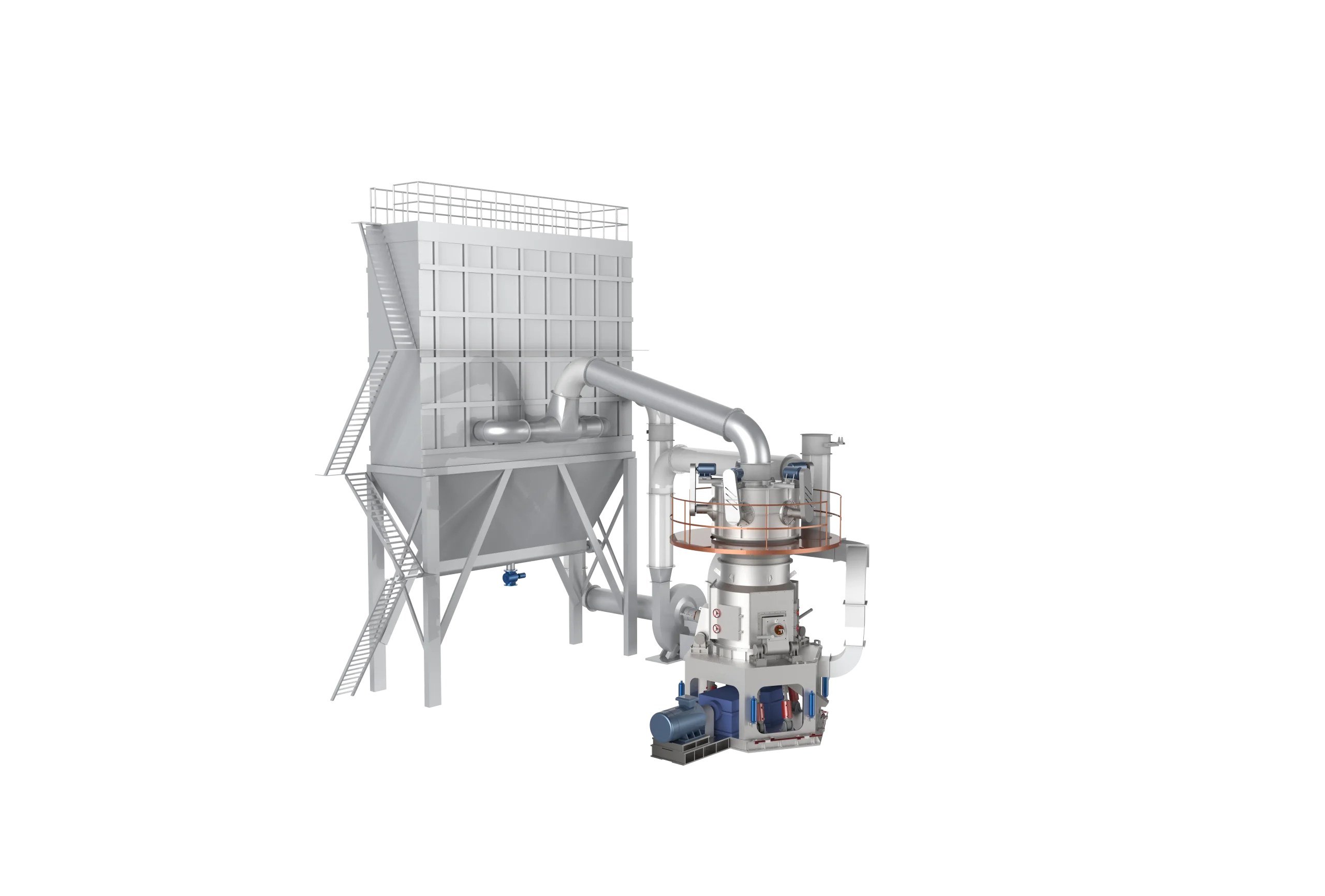

Grinding module

Basic configuration of the Grinding module

- hand valve

- feeder

- O-type screw conveyor

- Grinding machine

- Plate chain elevator

5

Grinding module

Basic configuration of the Finished module

- finished product hopper

- Antispin level device

- vibration motor

- Conveying system

- Packaging system

Advantages of Our Hydrated Lime Production Line

Differents between our machine and others

The final product performance comparison

Conveying system

Parameters of Hydrated Lime Production Line

| Technology | 5-8TPH Ordinary powder Plant | 10-15TPH Ordinary powder Plant | 10-15TPH Fine powder production line | 10-15TPH Full-quality powder production line | 15-20TPH Full-quality powder production line |

| Power(KW) | 370 | 412.7 | 570.1 | 588.95 | 746.35 |

if you are interested in our Hydrated Lime Production Line, please get in touch with me in the following ways: