Fujian province annual production line of 100,000 tons of calcium oxide and 200,000 tons of calcium hydroxide

1. It can be used in the flocculation treatment of industrial wastewater such as papermaking, petroleum, chemistry, metallurgy, metals, mineral processing, food, dyeing, etc., to adjust the pH value of tap water and acidic wastewater and to condition sludge.

2. It is used in industries such as thermal power plant desulfurization, flue gas desulfurization, deacidification, termination of phosphates and most heavy metals. It is also used as a raw material for the manufacture of calcium carbide, soda ash, and bleaching powder, and as a raw material for epoxy adhesives. It is also used in building materials, metallurgical fluxes, and cement accelerators. It is also used as plant deoiling and decolorizing agent, soil conditioner and boiler plant protective agent.

3. It can also be used in wastewater to remove phosphates and most heavy metals, disinfect and sterilize, remove ammonia nitrogen from water, break emulsions and coagulate, etc.

Site situation

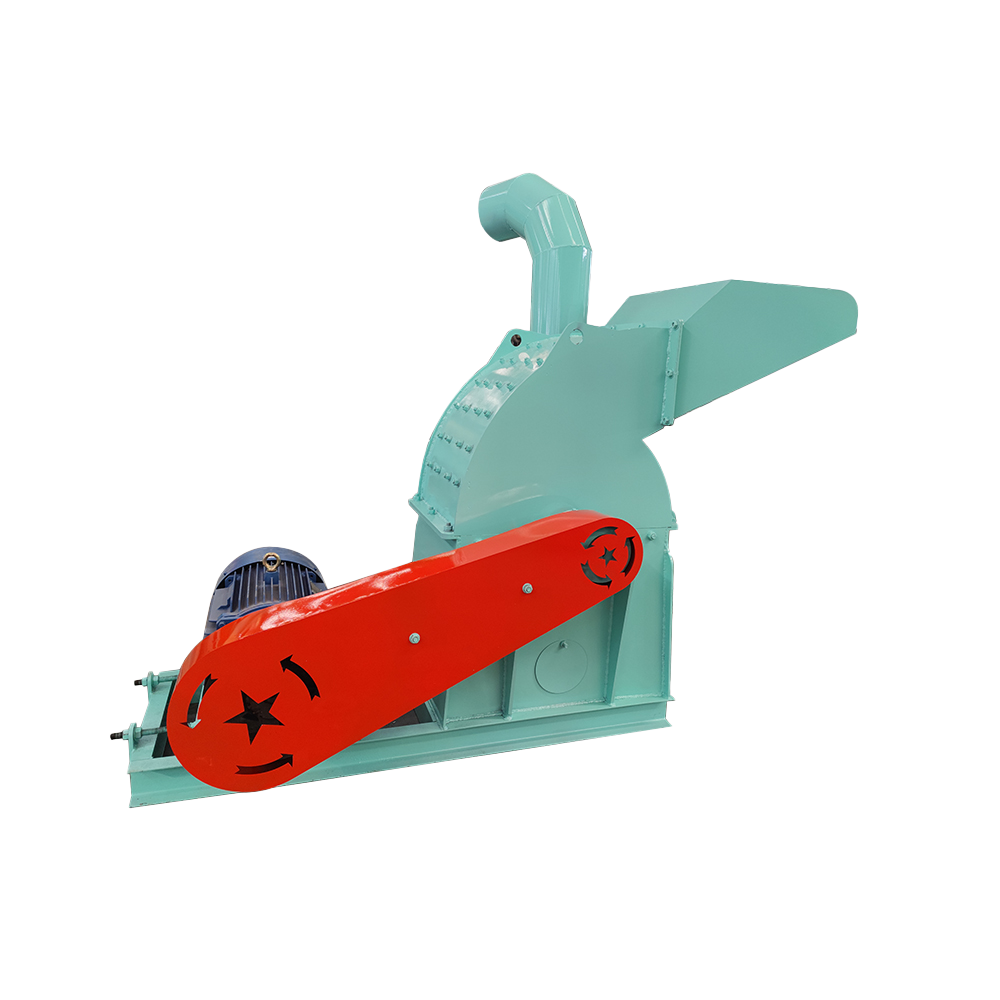

After the lumpy lime is initially digested by the Cronus lime digester, it then enters the customized digestion tank for secondary digestion to obtain more finished products. The finished product can be directly passed through a special calcium hydroxide powder separator to high-grade calcium hydroxide powder, and the tailings can be processed into a 325-mesh fine powder through a special calcium hydroxide grinding mill.

Customer Reviews

The Raymond mill originally used by other factories did not work well. Later, a Cronus calcium hydroxide mill was installed, which doubled the production capacity with the same power. Later, our company installed the entire calcium hydroxide production line. The stability of the product and the energy consumption of the production line are indeed higher than those of other nearby manufacturers that produce calcium hydroxide powder. We are very satisfied.