Contents Catalog

1. Introduction

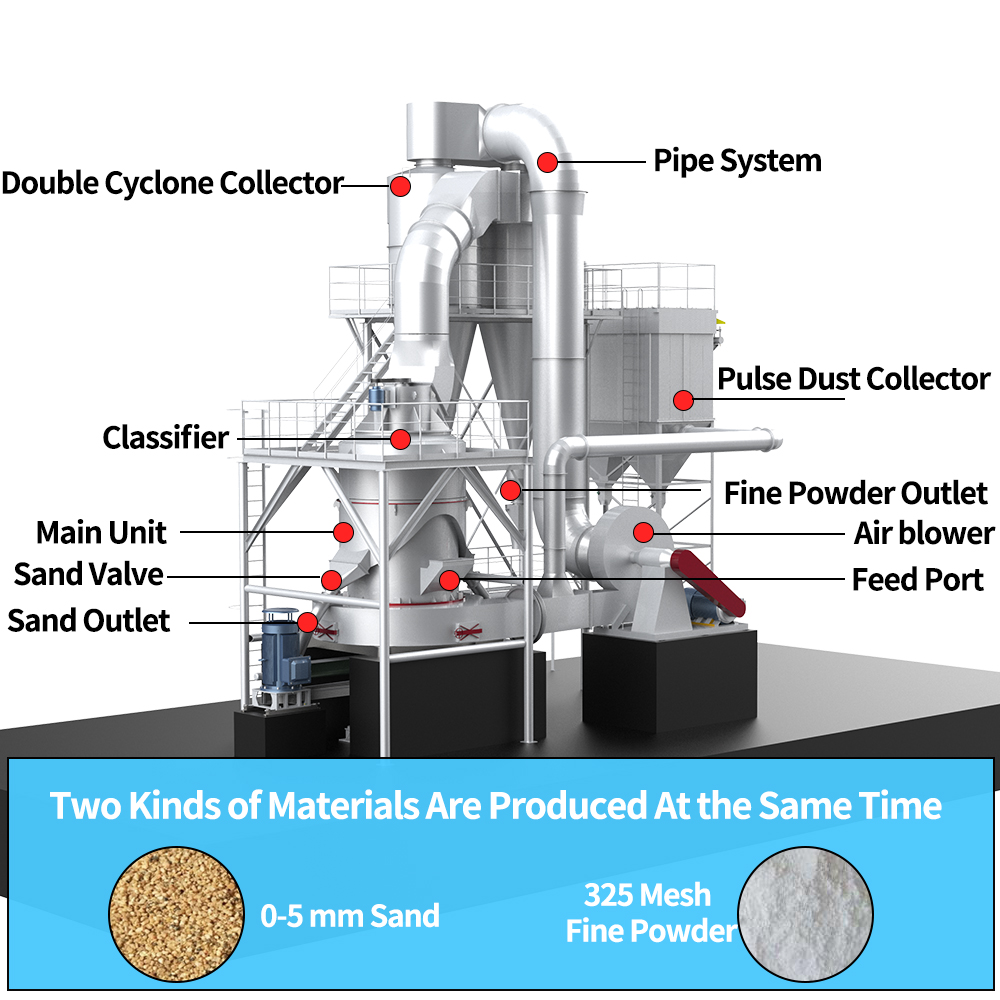

Raymond Mill is a high-efficiency grinding equipment widely used in the mineral processing industry, especially for grinding materials with high hardness. Its working principle involves the relative motion between the grinding roller and the grinding ring, which grinds materials into fine powder. The design features of Raymond Mill offer significant advantages in terms of high efficiency, energy savings, and adjustable particle size, making it widely applicable for processing ores, non-metallic minerals, and various other materials.

2. Introduction to Quartz Stone

Quartz stone is primarily composed of silicon dioxide (SiO₂), and it is widely found in nature. It has a high hardness (7 on the Mohs scale) and excellent chemical stability, making it resistant to many chemical agents. Quartz stone is extensively used in industries such as construction materials, decorative materials, optical glass, electronic devices, and semiconductors. Since quartz stone typically has a large particle size, it often requires fine grinding to meet the needs of different industrial applications.

3. Application of Raymond Mill in Quartz Stone Processing

The application of Raymond Mill in quartz stone processing can be summarized in the following aspects:

• Quartz Stone Crushing: Raymond Mill efficiently grinds quartz stone into fine powder, meeting the needs of industries such as construction materials, glass, and ceramics for quartz powder.

• Improving Quartz Stone Utilization: Raymond Mill can grind quartz stone into powders of different particle sizes, especially suitable for processing high-purity quartz stone, thus improving its utilization in industrial applications. By controlling the operational parameters of Raymond Mill, it is possible to achieve the required fineness for different industries.

• Glass Manufacturing: Quartz powder is a key raw material in glass manufacturing. Raymond Mill can grind quartz stone powder to meet the particle size requirements for glass production, ensuring the quality of the glass.

• Ceramics Industry: In ceramics production, quartz powder is used to improve the hardness and wear resistance of ceramic products. Raymond Mill helps achieve the required fineness to ensure the superior performance of ceramic products.

• Refractory Materials: Quartz stone, as a high-quality refractory material, can be processed by Raymond Mill to provide the appropriate particle size to meet the needs of high-temperature material applications.

4. Advantages

• High Efficiency and Energy Savings: Raymond Mill has high grinding efficiency, ensuring high output while maintaining low energy consumption when processing hard minerals such as quartz stone. Compared to other grinding equipment, Raymond Mill effectively reduces production costs.

• Adjustable Particle Size: The particle size of Raymond Mill products can be adjusted according to requirements. Users can finely control the product particle size by adjusting parameters such as airflow and feed rate to meet the specific needs of different industries.

• Simple Operation and Easy Maintenance: Raymond Mill has a simple structure and is easy to operate. Daily maintenance is also straightforward. Operators only need to set the parameters according to requirements to start the equipment, and maintenance does not require complex procedures, greatly reducing maintenance costs and downtime.

• Strong Adaptability: Raymond Mill is not only suitable for quartz stone but also for processing various ores and non-metallic minerals. It has strong adaptability and can meet different processing requirements.

• High Processing Capacity: Raymond Mill has a high processing capacity, making it particularly suitable for large-scale processing of quartz stone and other minerals. Its production efficiency can meet the demands of large-scale industrial production.

• Low Pollution: Raymond Mill adopts a sealed design that effectively controls dust emissions, reducing environmental pollution and meeting modern environmental protection standards.

Raymond Mill’s application in quartz stone processing can effectively improve the utilization rate of quartz stone and meet the stringent particle size requirements in various industrial fields. The quartz powder processed by Raymond Mill is widely used in industries such as glass, ceramics, refractory materials, and construction materials, enhancing the production efficiency and product quality of these industries. Furthermore, the high efficiency, energy savings, simple operation, and low pollution of Raymond Mill make it an ideal device for quartz stone processing and other mineral treatments.