Raymond mill is a kind of equipment used for high-fine powder processing of more than 280 kinds of materials in mining, chemical, construction and other industries.

It is suitable for processing various non-flammable and explosive materials with Mohs hardness below 7 and humidity below 6%. The fineness of the finished product is between 613μm and 44μm. Through the joint action of the analyzer and the fan, it can meet the use requirements of different users.

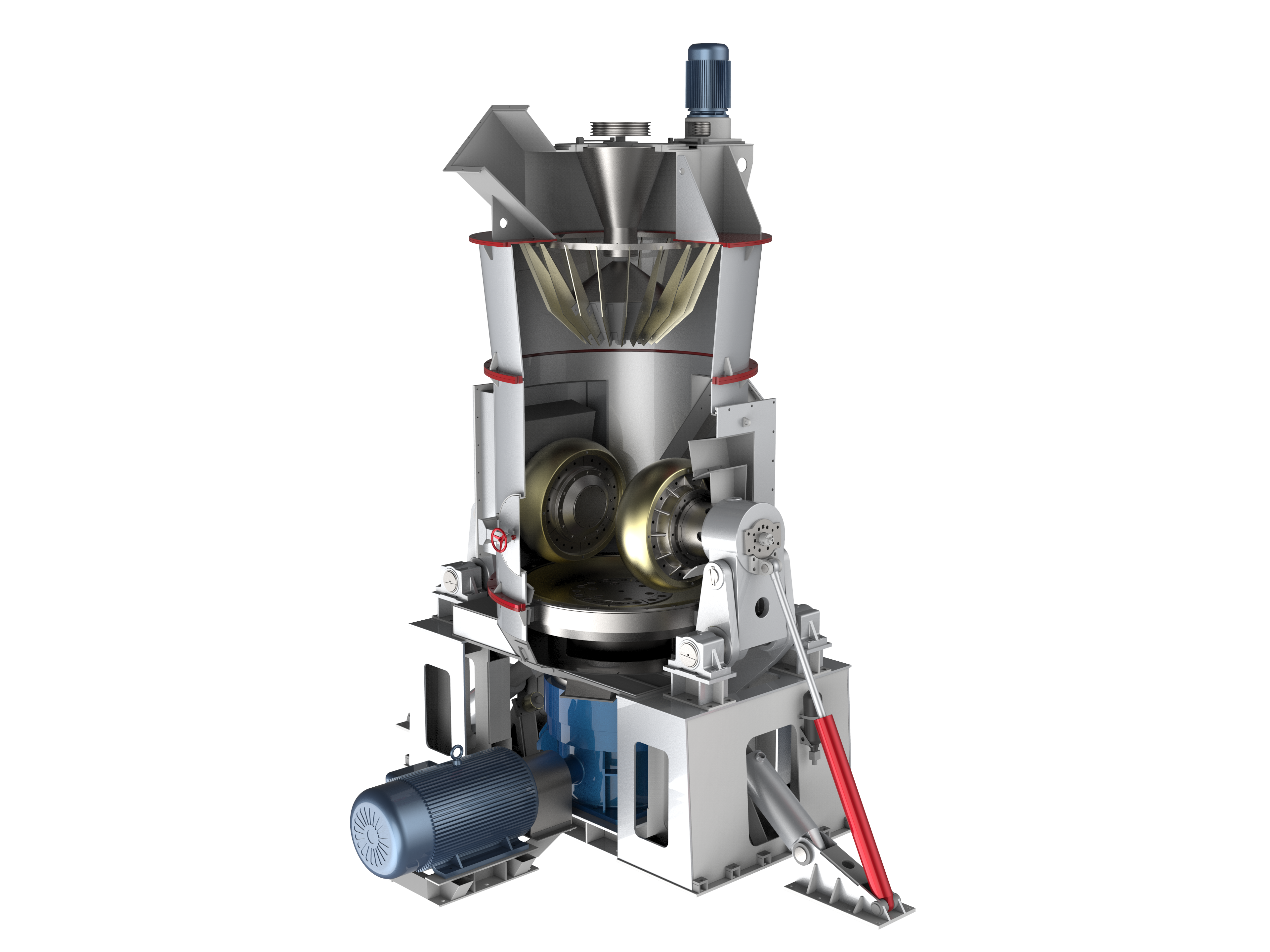

Raymond Mill Working Principle

The whole structure of Raymond mill is composed of main machine, analyzer, pipeline device, blower, finished product cyclone separator, jaw crusher, bucket elevator, electromagnetic vibrating feeder, electronic control motor, etc. The main machine of Raymond mill is composed of frame, air inlet volute, scraper, grinding roller, grinding ring, cover and motor.

When Raymond Mill Working, the material to be crushed is added into the machine from the feed hopper on the side of the cover. The grinding roller device hanging on the main machine plum blossom frame revolves around the vertical axis and rotates at the same time. Due to the centrifugal force during rotation, the grinding roller swings outward and presses against the grinding ring, so that the scraper scoops up the material and sends it between the grinding roller and the grinding ring. The purpose of crushing the material is achieved due to the rolling and crushing of the grinding roller.

Performance characteristics

- The whole machine is a vertical structure with a small footprint and strong system. From the rough processing of raw materials to transportation to powder making and final packaging, it can form an independent production system.

- Compared with other grinding equipment, the screening rate is as high as 99%.

- The main transmission device adopts a closed gear box and pulley, which has stable transmission and reliable operation.

- The important parts of the Raymond mill are made of high-quality castings and profiles, with fine craftsmanship, ensuring the durability of the whole set of equipment.

- The electrical system of the Raymond mill adopts centralized control, with advanced and reasonable selection and high degree of automation.

Why choose cronus’s Raymond mill?

Cronus provides comprehensive after-sales service and technical support, including equipment installation and commissioning, operation training and subsequent maintenance services, to ensure that you can use the equipment efficiently and quickly solve possible problems.