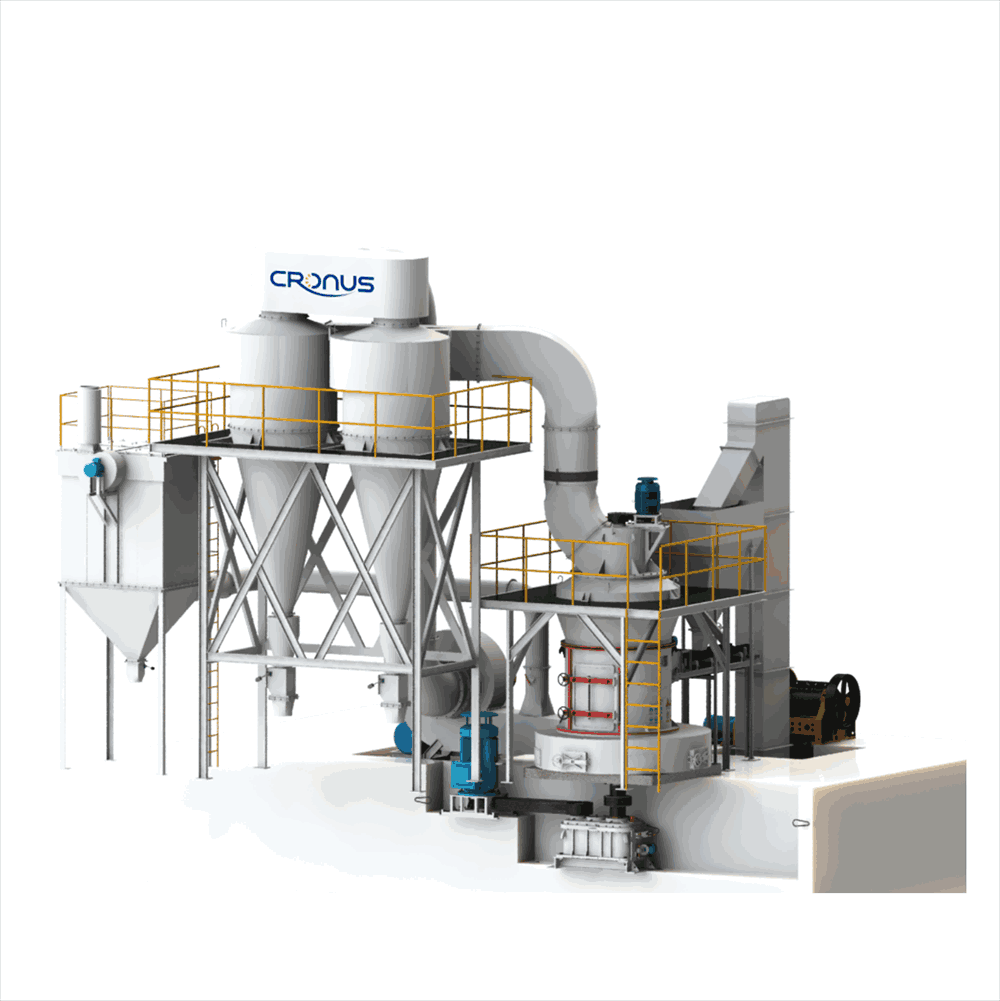

Contents Catalog

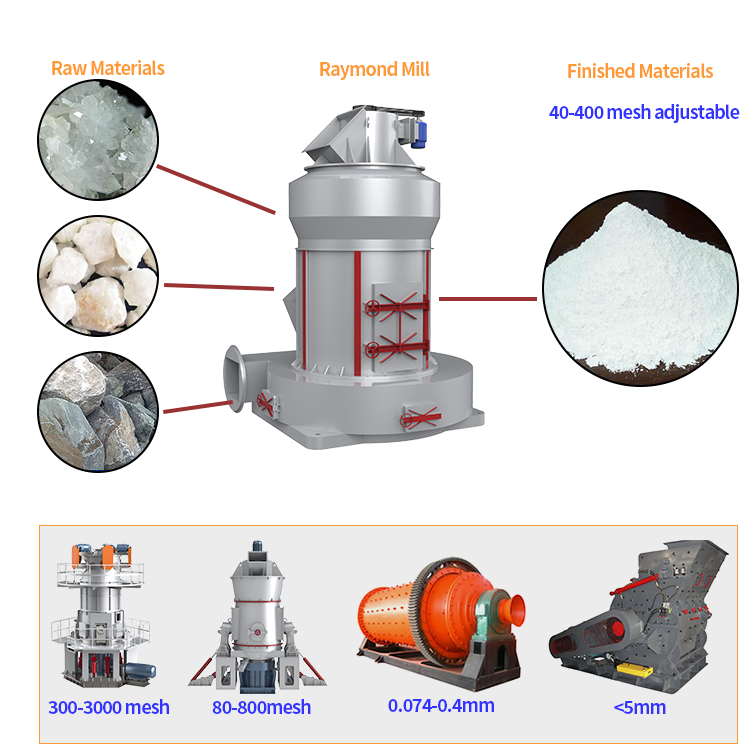

Raymond mill processed materials

Raymond Mill is suitable for huge capacity production and is widely used in grinding non-flammable and non-explosive materials under 7(the Moh’s hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash, carborundum, coal, etc.

Calcium carbonate crushing processing, gypsum crushing processing, power plant desulfurization, non-metallic ore pulverizing, and pulverized coal preparation.

Applications: Metallurgy, chemical engineering, building materials, mining, pharmacy, cosmetics and other fields

Raymond Mill Performance Advantage

Advantage 1

Low loss and high fineness: tear and wear parts use high-quality wear-resistant materials, the service life is over a year, and the final fineness is up to D97 5um

Advantage 2

With a centralized control electrical system, the workshop can achieve unmanned operation.

PLC intelligent control system, Siemens high-end Motor

Advantage 3

Easy to control and maintain, reliable operation.

The core components adopt high-performance, high wear resistance, and cost-saving materials.

Technical parameters of Raymond mill

| Model | Feed particle size (mm) | Product granularity (mm) |

Overall dimensions (Length * width * height(mm) (Does not include dust collector) |

Capacity(t/h) | power(kW) | ||

|---|---|---|---|---|---|---|---|

| Main Machine | Fan | Classifier | |||||

| 4R3220 | 20 | 0.045~0.18 | 6950×4570×8295 | 1~6 | 45 | 45 | 15 |

| CR1280 | 20 | 8400×5650×8200 | 1.5~10 | 55 | 55 | 15 | |

| 5R4128 | 20 | 8660×6050×9250 | 2~15 | 90 | 90 | 22 | |

| CR1500 | 20 | 8700×5500×9250 | 3~18 | 110 | 110 | 22 | |

| CR1620A | 30 | 9670×5570×10550 | 5~22 | 160 | 132 | 30 | |

| CR1700 | 30 | 9670×5570×10550 | 6~28 | 185 | 160 | 37 | |

| CR1850 | 30 | 10455×6830×9815 | 6.5~30 | 200 | 200 | 37 | |

| CR1920 | 30 | 13312×7690×9815 | 7.5~33 | 220 | 200 | 45 | |

| CR2150 | 30 | 11080×7600×11150 | 10~40 | 250 | 250 | 45 | |

| CR2500 | 35 | 11480×7730×11250 | 11.5~50 | 280 | 280 | 45 | |

OUR Service