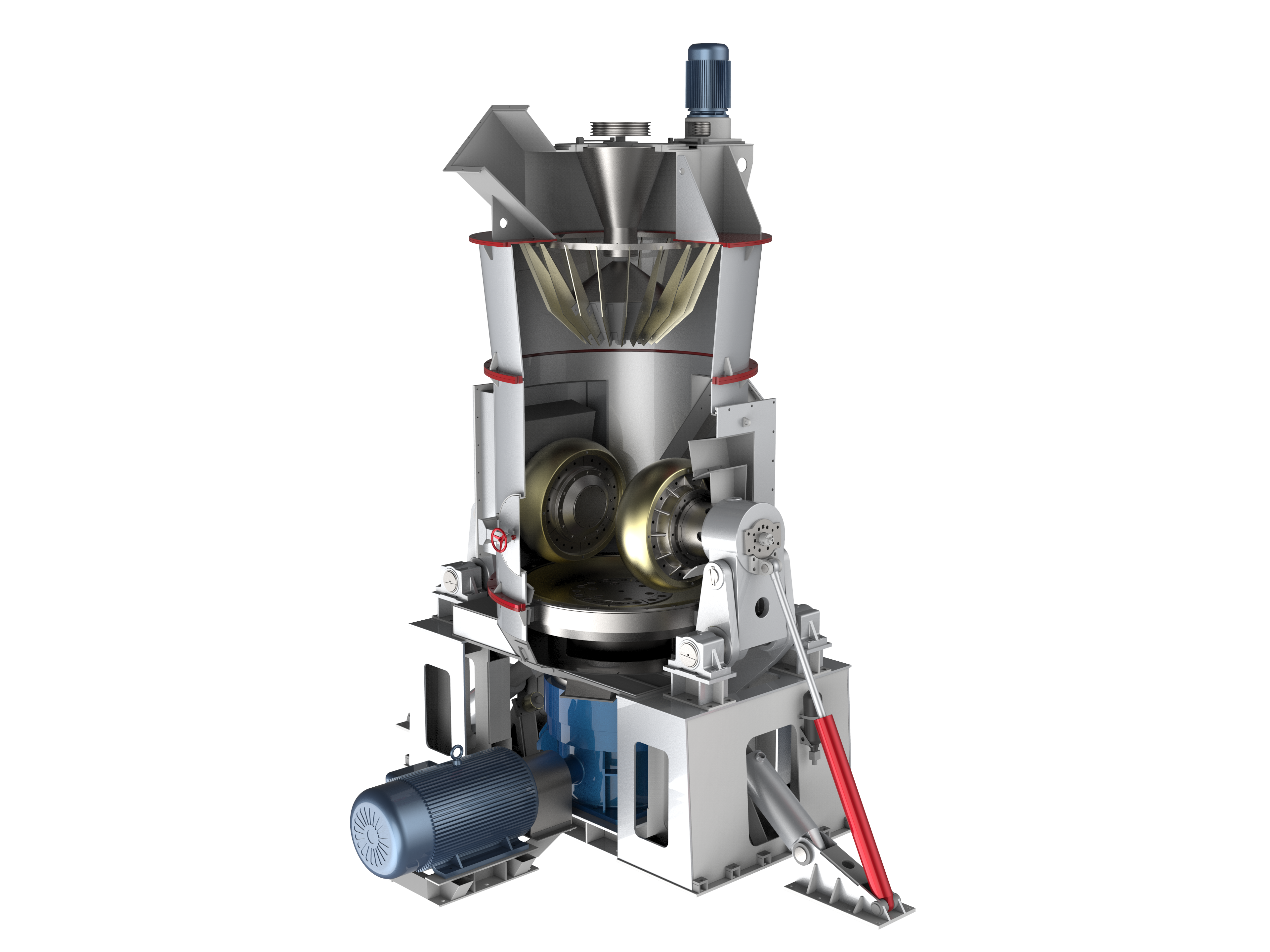

If you want to understand the operating principle and maintenance method of Raymond mill, you need to know the structure of Raymond mill. Raymond mill consists of main machine, analyzer, blower, finished product cyclone separator, pipeline device, motor, etc.

The main machine consists of frame, air inlet volute, scraper, grinding roller, grinding ring, cover and motor. Auxiliary equipment includes jaw crusher, elevator, electromagnetic vibrating feeder, electric control cabinet, etc., which can be flexibly selected according to the on-site situation. Let’s talk about the working principle of Raymond mill.

Working principle of Raymond mill

After the material is crushed to the required particle size, the elevator sends the material to the storage hopper, and then the vibrating feeder sends the material evenly and continuously into the grinding chamber of the Raymond mill main machine. Due to the centrifugal force during rotation, the grinding roller swings outward and presses against the grinding ring. The scraper scoops up the material and sends it between the grinding roller and the grinding ring. The grinding roller rolls to achieve the purpose of crushing.

The fine powder after grinding is brought into the analyzer for sorting with the circulating air of the blower. The material with too coarse fineness falls back to the re-grinding, and the qualified fine powder enters the finished product cyclone powder collector with the air flow and is discharged through the powder outlet pipe to become the finished product.

In the grinding chamber of the Raymond mill, there is a certain amount of moisture in the material to be ground, heat is generated during grinding, water vapor evaporates, and the interfaces of the pipelines of the whole machine are not tight, so the external gas is sucked in, which increases the circulating air pressure, ensuring that the mill works under negative pressure. The increased air flow is discharged into the dust collector through the residual air duct and discharged into the atmosphere after purification.

Here is the translated parameter comparison table in English:

| Model | Maximum Feed Size (mm) | Finished Product Size (mm) | Dimensions (LWH) (mm) (Excluding Dust Collector) | Output (t/h) | Power (kW) |

|---|---|---|---|---|---|

| Main Unit | |||||

| CR3220 | 20 | 0.045~0.18 | 6950×4570×8295 | 1~6 | 45 |

| CR1280 | 20 | 0.045~0.18 | 8400×5650×8200 | 1.5~10 | 55 |

| CR4128 | 20 | 0.045~0.18 | 8660×6050×9250 | 2~15 | 90 |

| CR1500 | 20 | 0.045~0.18 | 8700×5500×9250 | 3~18 | 110 |

| CR1620A | 30 | 0.045~0.18 | 9670×5570×10550 | 5~22 | 160 |

| CR1700 | 30 | 0.045~0.18 | 9670×5570×10550 | 6~28 | 185 |

| CR1850 | 30 | 0.045~0.18 | 10455×6830×9815 | 6.5~30 | 200 |

| CR1920 | 30 | 0.045~0.18 | 13312×7690×9815 | 7.5~33 | 220 |

| CR2150 | 30 | 0.045~0.18 | 11080×7600×11150 | 10~40 | 250 |

| CR2500 | 35 | 0.045~0.18 | 11480×7730×11250 | 11.5~50 | 280 |

| CR2750 | 35 | 0.045~0.18 | 17000×11000×15000 | 15~80 | 450 |

- The above data is for reference only. For specific information, please refer to the product or its manual.

Advantages of Raymond Mill

The entire Raymond Mill is a vertical structure with a relatively small footprint and strong system. It can form an independent production system from the rough processing of raw materials to transportation to powder making and final packaging.

Compared with other grinding equipment, the Raymond Mill has a high screening rate of up to 99%, which is generally unattainable by other grinding equipment.

The main transmission device of the Raymond Mill adopts a closed gear box and pulley, with stable transmission and reliable operation.

The important parts of the Raymond Mill are made of high-quality castings and profiles, with fine craftsmanship and rigorous processes, which ensure the durability of the entire set of equipment.

The electrical system adopts centralized control, and the grinding workshop can basically realize unmanned operation, and maintenance.

Maintenance methods of Raymond mill

During the use of the mill, there should be a fixed person responsible for supervision, and the operator needs to have a certain technical level. Before the installation of the mill, the operator needs to undergo necessary technical training to make him understand the principle and performance of the Raymond mill and be familiar with the operating procedures.

In order to make the mill normal, the “equipment maintenance and safety operation system” should be formulated to ensure the long-term safe operation of the mill, and necessary maintenance tools, grease and corresponding accessories should be available.

After the Raymond mill has been used for a period of time, it should be overhauled, and the grinding roller, grinding ring, scraper and other wearing parts should be overhauled and replaced. The connecting bolts and nuts of the grinding roller device should be carefully checked before and after use to see if there is any looseness and whether the lubricating grease is sufficient.

When the grinding roller device is used for more than 500 hours and the grinding roller is replaced again, the rolling bearings in the roller sleeve need to be cleaned, and the damaged parts should be replaced in time. The refueling tools can be manual refueling pumps and grease guns.

Fineness adjustment, according to the size, hardness, moisture content, specific gravity of the material, the processing fineness is also different, the upper analyzer can be adjusted, high speed, high fineness, low speed, low fineness. Increasing the fineness will reduce the output accordingly. If it still does not meet the requirements, the fan speed should be adjusted, and the user can flexibly control it.

The scrap limit of the grinding roller and grinding ring is not less than 10mm.

When the Raymond mill stops, stop feeding first, and the main machine continues to grind, so that the residual abrasive continues to grind. After about one minute, the main machine motor and analyzer motor can be turned off to stop the grinding work, and then the fan motor can be stopped to blow away the residual powder.

If you are looking for an efficient and reliable Raymond mill, Cronus is your best choice! We provide advanced Raymond mill equipment, suitable for multiple industries such as mining, building materials, chemicals, etc., ensuring excellent grinding results and stable performance. Cronus not only provides high-quality equipment, but also provides customers with comprehensive technical support and after-sales service to ensure that your equipment is always in the best condition. Contact Cronus now and let our professional team tailor a solution for you to help you improve your production efficiency!