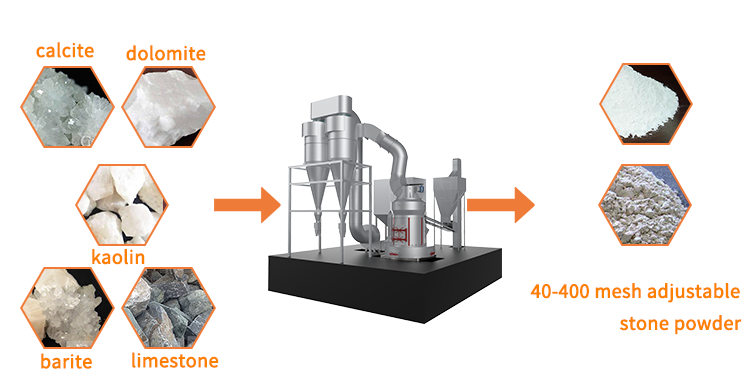

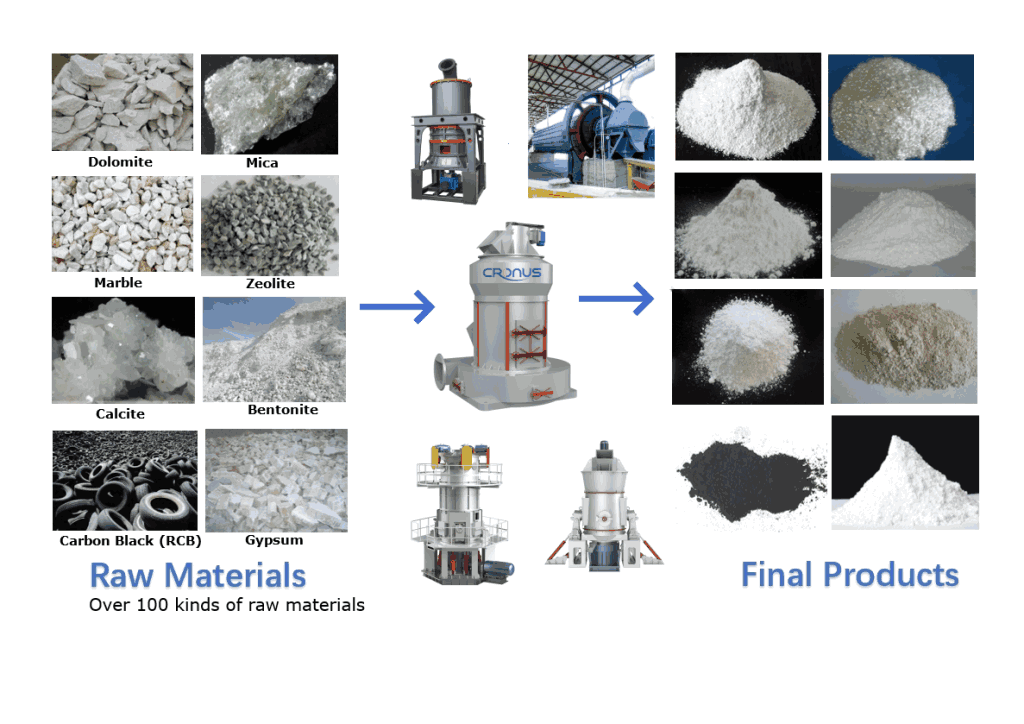

Raymond mills are widely used grinding equipment. Due to their unique features and capabilities, they have found applications in numerous industries.

I. Applications of Raymond Mill

1. Mining Industry

In the mining sector, Raymond Mill is crucial for processing various ores. For example, it is used to grind limestone, which is a common building material and also has applications in the chemical industry. The mill can effectively reduce the large chunks of limestone into fine powder, which can then be used in the production of cement, lime, and other calcium-based products. It is also applicable in grinding ores such as gypsum. Gypsum powder obtained from Raymond mill is used in the manufacture of plasterboards and cement additives. The precise grinding ability of the Raymond mill ensures that the particle size of the ore powder meets the specific requirements of different downstream processes in the mining and mineral processing industry.

2. Chemical Industry

In the chemical industry, Raymond Mill is used to grind a variety of chemical substances. It can handle materials like potassium carbonate, which is used in the production of fertilizers, detergents, and various chemical reagents. The mill is capable of producing a uniform particle size distribution, which is essential for the quality and performance of chemical products. For example, in the production of pigments and dyes, a fine and consistent particle size is required to ensure proper color dispersion and stability. Raymond mill can achieve the necessary grinding fineness, enabling the chemical industry to produce high-quality products with enhanced properties.

3. Food and Pharmaceutical Industry

In the food industry, Raymond mill is used for grinding food ingredients such as starch, sugar, and salt. It can produce a very fine powder of these substances, which is beneficial for improving the texture and solubility of food products. In the pharmaceutical industry, it is used to grind active pharmaceutical ingredients (APIs) and excipients. For instance, some drugs need to be in a fine powder form for better absorption in the body. Raymond mill can grind these substances under strict hygienic conditions, meeting the high standards of the pharmaceutical industry. It helps in the production of tablets, capsules, and other pharmaceutical formulations by providing the required particle size and powder characteristics.

4. Construction and Building Materials Industry

For the construction and building materials industry, Raymond mill is used to produce powders of materials like silica sand, feldspar, and mica. These powders are used in the manufacturing of glass, ceramics, and various building materials. In the production of glass, the fine grinding of silica sand by Raymond mill is essential to obtain a homogeneous mixture that can be melted and formed into high-quality glass products. In ceramics, the milled powders contribute to the formation of a dense and strong ceramic body, enhancing the mechanical properties and appearance of ceramic products.

II. Advantages of Raymond Mill

1. High Grinding Efficiency

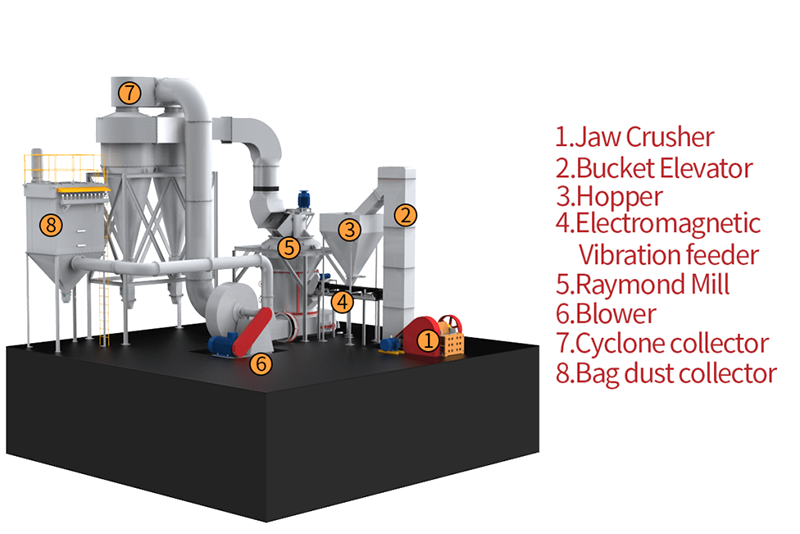

Raymond mill is designed with a unique grinding mechanism. It has a central shaft with grinding rollers and a grinding ring. The rollers, under the action of centrifugal force, roll against the grinding ring, effectively crushing and grinding the materials. This design allows for a continuous grinding process, which results in high production efficiency. Compared to some traditional grinding mills, Raymond mill can process a larger amount of materials in a shorter time, reducing the overall production cycle and increasing the output of the enterprise.

2. Fine Grinding Fineness

It can achieve a very fine grinding fineness, usually ranging from 80 to 325 mesh or even finer. This is especially important in industries such as the chemical and pharmaceutical industries where the particle size of the product directly affects its quality and performance. The adjustable grinding fineness feature of Raymond mill enables it to meet the diverse requirements of different products. By adjusting the gap between the grinding rollers and the grinding ring, the desired particle size of the powder can be obtained, providing great flexibility in production.

3. Low Energy Consumption

Raymond mill is relatively energy-efficient. The design of its transmission system and grinding chamber is optimized to reduce energy losses during operation. The motor drives the main shaft and the grinding rollers to rotate, and the energy is effectively utilized in the grinding process. Compared to some high-energy-consuming grinding equipment, Raymond mill can save a significant amount of electricity costs in the long run. This is beneficial for enterprises in terms of reducing production costs and improving their competitiveness in the market.

4. Simple Operation and Maintenance

The operation of Raymond mill is relatively simple. It has a user-friendly control panel that allows operators to easily adjust the parameters such as the feeding rate, grinding fineness, and motor speed. In terms of maintenance, the structure of Raymond mill is designed for easy access and replacement of wearing parts. The grinding rollers and grinding ring are the main wearing parts, and they can be easily replaced when worn out. This reduces the downtime of the equipment and ensures the continuous operation of the production line.

5. Good Sealing Performance

Raymond mill has a good sealing design. During the grinding process, it can effectively prevent the leakage of powder and dust. This is crucial in industries such as the food and pharmaceutical industries where hygiene and environmental protection are of great importance. The good sealing performance not only ensures the quality of the product but also protects the working environment and the health of the operators. It also helps to reduce material losses and improve the overall production efficiency.

In conclusion, Raymond mill has a wide range of applications in various industries and offers significant advantages in terms of grinding efficiency, fineness, energy consumption, operation, maintenance, and sealing. Its versatility and reliability make it an essential grinding equipment in modern industrial production.